Perceptions on construction-related factors that affect concrete quality, costs and production

Percepciones de los factores relacionados a la construcción que afectan la calidad del hormigón, costos y producción

ACI Avances en Ciencias e Ingenierías

Universidad San Francisco de Quito, Ecuador

Received: 21 November 2017

Accepted: 25 December 2018

Abstract: Structured and unstructured factors affect concrete product. Structured factors are related to concrete production and unstructured factors are related to the construction process. This study focuses on examining the perceived importance of unstructured factors (i.e, construction-related factors) on concrete compressive strength, concrete costs and production rates on the jobsite and understanding the influence of construction experts' characteristics, such as profession, on their perceptions. A comprehensive literature review was performed to identify unstructured factors. A survey was then designed and deployed to 297 experts from the construction industry and academia to examine the importance of the identified factors through the relative importance index (RII) method and to further identify additional unstructured factors. Likert aggregation and tests for eguality of odds were used to compare and analyze responses of two groups of participants, namely architects and engineers. Curing humidity, crew experience and compaction method are the top three factors perceived to affect concrete compressive strength, whereas crew experience, mixing time and compaction method are the factors perceived to affect concrete costs and production rates the most. Crew experience, compaction method and mixing time dominate the global ranking of perceived affecting factors for concrete compressive strength, costs and production rates. Architects were found to be more likely to perceive high or very high impacts of these factors on concrete. The present study increases our understanding of construction-related factors to facilitate project management and preserve concrete characteristics.

Keywords: Affecting factors, compressive strength, concrete, costs, production, quality.

Resumen: El hormigón es afectado por los llamados factores estructurados y no estructurados. Los primeros están relacionados a la producción del hormigón mientras gue los factores no estructurados están relacionados con el proceso constructivo. Este estudio se enfoca en examinar la importancia percibida de los factores no estructurados en el esfuerzo de compresión del hormigón, sus costos y producción en la obra; así como también, en comprender la influencia de la tipología de los expertos en construcción, como la profesión, en sus percepciones. Una amplia revisión de la literatura fue llevada a cabo para identificar los factores no estructurados. Una encuesta fue diseñada y enviada a 297 expertos de la industria de la construcción y academia para examinar la importancia de los factores identificados en la literatura a través del método del índice de importancia relativa (RII) e identificar factores no estructurados adicionales. Agrupación Likert y pruebas de igualdad de chances fueron utilizadas para comparar y analizar las respuestas de dos grupos de participantes: arquitectos e ingenieros. Humedad de curado, experiencia de la cuadrilla y el método de compactación son los tres factores más importantes percibidos que afectan el esfuerzo de compresión del hormigón, mientras que la experiencia de la cuadrilla, el tiempo de mezclado y el método de compactación son los factores percibidos que más afectan los costos y tasas de producción del hormigón. La experiencia de la cuadrilla, el método de compactación y el tiempo de mezclado dominan el ranking global de los factores percibidos que afectan al esfuerzo de compresión, los costos y tasas de producción del hormigón. Se encontró que los arquitectos son los más propensos a percibir altos o muy altos impactos de estos factores en el hormigón. El presente estudio incrementa nuestro entendimiento de los factores no estructurados para facilitar el manejo de un proyecto y preservar las características del hormigón.

Palabras clave: Calidad, costos, esfuerzo de compresión, hormigón, factores gue afectan, producción.

INTRODUCTION

Concrete is a construction material made of water, Portland cement, aggregates and admixtures, which are mixed together in specific proportions to meet construction specifications for such qualities as compressive, tensile or flexural strength. In addition to steel, concrete is one of the two most popular construction materials currently used in the construction industry, and it is the second most utilized product in the world after water [1,2], Moreover, concrete demand increases every day, due to its properties and increases in population around the world. In fact, in the United States, around 260 million cubic yards of concrete are used each year by the construction industry [3],

Concrete compressive strength is commonly used to measure concrete quality, and it is an important para meter for designers and for concrete quality control [4,5], Compressive strength is used for measuring concrete quality because concrete is mainly employed to withstand compression forces. Therefore, compressive strength is the quality metric used for judging concrete quality in this study.

Concrete quality should be ensured from its production to its final placement into the forms, finishing and curing on any construction site. Ready-mixed concrete undergoes stringent quality controls during its production and transportation. However, there are several uncertain factors or conditions that are not considered after concrete trucks arrive at a construction site that can change the characteristics of the final concrete product [1], In addition, when concrete is fabricated in situ, additional factors may affect concrete quality and can cause possible significant changes in its mechanical properties. Several prior studies have investigated the impact that factors related to the production of concrete – including raw material properties or mixture designs – have on concrete quality, such as the influence of water-cement ratio, entrained air, aggregate size and age on compressive strength and the effects of admixtures on concrete compressive strength [1, 4-7]. With respect to costs and production rates, studies of affecting factors are scarce. O’Connor [8] pointed out that factors affecting crew production rates are difficult to measure and quantify due to intrinsic variables. Also, the author emphasized that the lack of existing actual data for specific activities containing particular details prevents researchers from accurately investigating construction time effects. Jarkas [9, 10] investigated the influence of buildability on labor productivity by employing experienced crews and argued other factors such as the level of crew skills and experience may influence concrete productivity and costs. Heravi and Eslamdoost [11] studied labor productivity factors in the construction industry in order to lower costs and project duration. However, the literature is limited regarding factors present when fabricating concrete and their impact on compressive strength as a quality metric, as well as on costs and production rates.

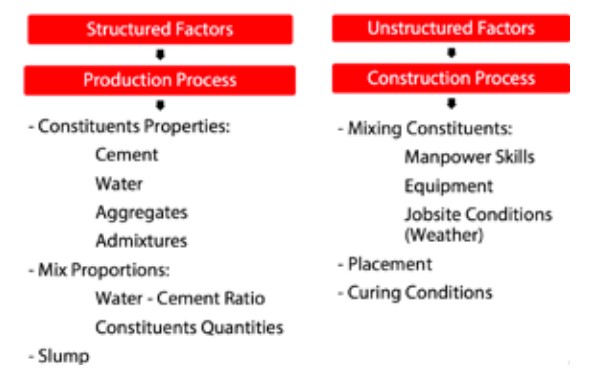

Yuan et al. [12] classified factors affecting concrete strength into two categories: structured and unstructured. Structured factors are factors related to the production of concrete ,such as raw materials quantities and quality and mix designs [12], As previously mentioned, these factors have already been studied deeply and, in fact, several correlations have already been proposed including the influence of water-cement ratio on compressive strength for non-air-entrained concretes [4], Unstructured factors are those associated with the construction process of a facility such as workforce skills and local conditions on the construction site; there is no clear understanding of their consequences on concrete strength [12], Fig. 1 summarizes the factors that affect the concrete production and construction processes.

Factors that affect concrete during its production and construction processes

Understanding the impact of construction specialists' attributes on their perceptions about factors affecting concrete performance is crucial so that appropriate actions can be taken to improve construction processes and management. Even though perception studies are not common in engineering, several studies have analyzed how subjects' characteristics influence their perceptions on engineering and construction issues [13], Dai et al. [14] studied the perceptions of construction workers regarding factors affecting their productivity by deploying a survey containing Likert-type questions. Lu and Yan [15] pointed out that knowledge of construction groups or individuals is limited regarding risk perception. Zhang et al. [16] suggested that understanding the risk perceptions of different groups such as architects and engineers allows adequate construction management, implying that the attributes of different groups of professionals influence their perceptions. Rodríguez-Garzón et al. [13], also using a questionnaire, studied the risk perception of construction workers in the context of uncertainty and occupational risk in the construction industry. Tymvios and Gambatese [17] claimed that comparing the responses of different groups allows one to identify the group that is more likely to support a perception. All studies imply that perceptions depend on the characteristics of an individual or a group of people sharing the same background, meaning that different groups (e.g., architects and engineers) have different perceptions due to intrinsic characteristics of each group. Thus, it is important to evaluate the impact of construction experts' characteristics on their perceptions about construction-related factors to facilitate project management and preserve concrete properties.

The main goal of this study is to increase our understanding about how unstructured factors affect concrete quality, costs and production rates. The objectives are: (1) identify and evaluate the perceived importance of construction-related factors that affect concrete compressive strength as a quality metric, as well as costs and production rates, and (2) measure how construction experts' characteristics influence their perceptions of these factors. These objectives will be accomplished by performing a comprehensive literature review, deploying a survey to construction experts and using RII and odds ratios to estimate their perceived importance. The results will inform project managers, superintendents and technicians, to prevent concrete quality from being influenced by affecting factors on the jobsite. In addition, current practices and mitigation actions are discussed for future research.

METHODOLOGY

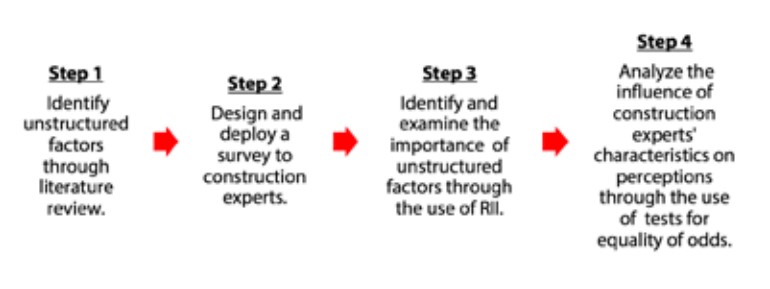

The proposed methodology investigates unstructured factors affecting concrete quality during the construction process, since these factors can cause important concrete quality variability and should be taken into consideration on the job site [12], To identify such unstructured factors, the research methodology shown in Fig. 2 was used.

The first step consisted of performing a review of relevant literature, to identify unstructured factors that affect concrete quality. Next, a survey was designed and deployed to construction experts (i.e., individuals with experience in the construction industry, such as contractors, architects, engineers and academics). This survey included questions about unstructured factors identified in the literature and asked for others that had been identified or recognized by the survey respondents throughout their careers. RII was then utilized to identify and evaluate the perceived importance of factors that highly affect concrete quality, costs and production rates. The quality metric for concrete was also determined from the literature and survey responses. Next, construction experts' characteristics, such as profession or experience, were analyzed through the use of Likert aggregation and 2x2 contingency tables (i.e., chi-square tests for equality of odds), to determine their influence on experts' responses. The techniques chosen for analysis responded to the study objectives and the properties of the survey data [18].

Research methodology

Identification of Unstructured Factors

Construction codes including the ACI building code play an important role when building with concrete. They attempt to preserve concrete final product by giving general guidelines that need to be taken into account during concrete fabrication; however, the aforementioned codes do not give specific recommendations regarding construction site conditions (i.e, unstructured factors) that may be present at the jobsite. Laungrungrong et al. [19] argued that the increasing use of concrete creates the necessity of having methods or techniques to control its quality and that failing to identify strength problems may cause project delays and cost overruns. The variability in concrete compressive strength may be caused not only by mixing incorrect quantities of its components or utilizing poor quality materials but also by concrete transportation, placement and compaction, implying that compressive strength not only depends on its production process but also on uncertain conditions on the construction site [20]. Thus construction site conditions should be not only identified but also require special attention.

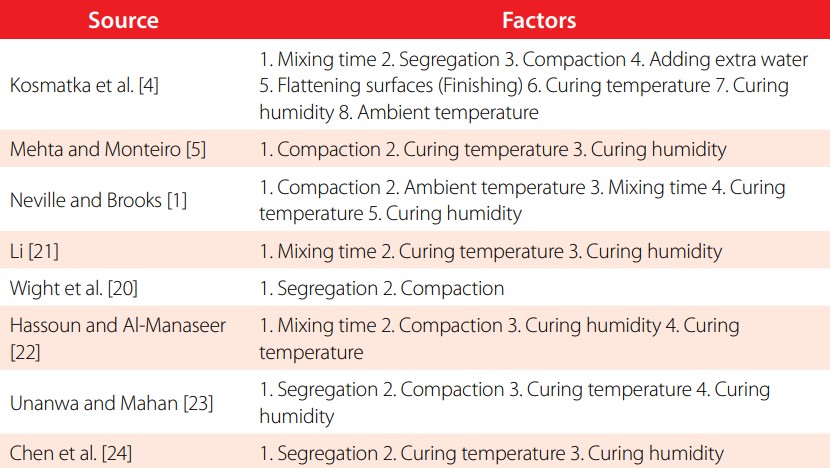

A comprehensive literature review was carried out tending to identify unstructured factorsaffectingconcretecompressivestrength,costsand production rates.Such process revealed several studies highlighting, mainly .factors affecting compressive strength as a guality metric. Neville and Brooks [1] pointed out that water-cement ratio, degree of compaction, age and ambient temperature (i.e., hot- and cold-weather concreting) should be taken into consideration in practice, in order to avoid compression strength reduction, implying that those factors should be monitored constantly. However, the study stated that there are other factors such as mixing time, curing temperature and humidity that should also be considered when making concrete. In addition, Li [21] mentioned water-cement ratio, cement content, aggregates, admixtures, mixing procedures and curing conditions as factors that influence concrete properties, recognizing influencing factors inherent to construction processes.

Moreover, Kosmatka et al. [4] argued that special attention should be paid to mixing time, placement, consolidation (i.e., by hand or mechanically), rain protection (to avoid adding extra water to the concrete), finishing operations (e.g, flattening surfaces), curing and protection from extreme temperature changes (i.e, curing temperature and humidity) and hot and cold weather concreting (i.e, ambient temperature) in order to maintain concrete quality. Mehta and Monteiro [5] argued that factors modifying concrete compressive strength include the proportions and materials of the concrete mixture and degree of consolidation and conditions of curing. The authors emphasized that concrete curing involves temperature, time and humidity conditions. Hassoun and Al-Manaseer [22] highlighted that methods of mixing, compaction and curing affect the compressive strength. Proper mixing time, the use of appropriate concrete mixers and the right use of vibrators have a positive effect on concrete by increasing its compressive resistance, which is the consequence of having a uniform mixture and reducing voids. Curing moisture and temperature also play an important role in the strength of concrete, since the hydration of cement depends on them.

In recent studies about concrete strength variability, Unanwa and Mahan [23] stated that strength variation is due to concrete placement, consolidation and curing methods (i.e., curing temperature and humidity), and Chen et al. [24] suggested that special attention should be paid to temperature and humidity when producing, placing and curing concrete, implying that concrete strength may be affected after mixing its component materials until it is finally placed.

Table 1 summarizes the preliminary construction site factors (unstructured factors) that affect concrete, as identified through the literature. However, relevant literature did not reveal the significance or effects of these unstructured factors on the concrete final product in terms of compressive strength, cost and production.

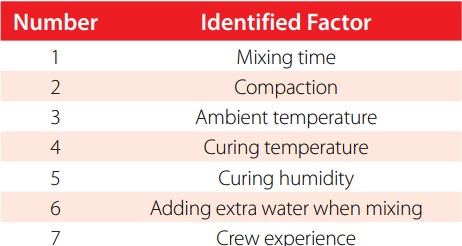

Table 1 shows that researchers agreed on several factors that affect concrete compressive strength. These studies assumed that concrete was made by laborers with experience or expertise fabricating concrete; construction workers with appropriate skills must be hired in order to ensure the success of a project [25], Therefore, crew experience could be another unstructured factor that affects concrete quality variability. Table 2 shows a compiled list of preliminary unstructured factors considered in this study. The factors are listed in no particular order.

Research methodology

Regarding the number of factors that may affect concrete, Day [26] appealed to Pareto's principle to say that 70% to 80% of the total variability in concrete strength is caused by two or th reefactors. The author suggested that strength variability is caused by less than ten factors, which is in agreement with what has been found elsewhere in the literature.

Finally, literature regarding factors that affect concrete compressive strength during its production until its final placement is limited. Most of the literature focuses on well known structured factors regarding concrete component properties and material proportions (e.g, water-cement ratio), and while the literature identifies unstructured factors, their impact on quality, cost and production has not been quantified.

Preliminary unstructured factors

Survey

Surveys are well-recognized tools that allow us to infer valuable knowledge about a population through the collection of guantitative and gualitative data, as long as the sample size chosen is representative of the actual population. The main purpose of any survey is to build guantitative descriptors (statistics) to summarize the observations [27]; however, survey variables will always contain bias due to nonresponses or measurements errors [28],

Groves et al. [27] stated that a survey should meet the following criteria to minimize errors: (1) respondents must describe their characteristics accurately, and; (2) respondents must be representative of the larger population. Meeting this criterion does not imply that survey statistics are error-free; errors of observation and non-observation will still be present in the results [27],

Thus, a survey was designed considering such criteria, and it was deployed online to a large group of construction experts in Ecuador who had at least one year of experience with concrete in the construction industry or academia. Survey respondents included members from professional associations of civil engineers and architects and from educational organizations such the School of Civil Engineering and Architecture of the Central University of Ecuador. This ensured that the respondents met the "expert" criteria. The study was granted an exemption through the pertinent Institutional Review Board (IRB) prior to conducting the investigation. The survey included a set of questions for identifying and ranking unstructured construction site factors that could affect concrete quality, costs and production rates during the construction process, as well as questions regarding concrete quality metrics and respondents' characteristics such as profession and construction experience.

Even though construction practices such as normal concrete fabrication at the jobsite are highly dependent on local and regional conditions, the questionnaire was intended and designed to explore construction site factors that are usually present when performing concrete operations regardless the location of the project. Regarding sample population, Ecuadorian construction practices regarding making concrete by hand at the jobsite are very similar to American practices since the Ecuadorian building code (NEC) and the Ecuadorian standards (NTEINEN) are based on the ACI building code and ASTM standards respectively, reducing possible limitations or significant bias on the results of this study. With respect to ready mixed concrete, prestressed construction or prefabrication, they are beyond of the scope of this study.

The survey was deployed online using the Qualities platform, and it was distributed to a group of approximately 5,000 active construction experts through their own organizational mailing list manager. The sample size of 297 valid responses ensured a confidence level of 95%. In addition, validation questions were included in the survey, to prevent respondents from answering survey questions randomly.

Sample Description

A total of 333 responses were collected during June and July of 2016 after deploying the online survey to construction experts. Out of the 333 total responses, 297 were valid. The sample exceeded the required sample size by 200 since only 97 valid responses were required to obtain a confidence level of 95% and a confidence interval of 10%, implying that the actual confidence interval was as low as 6%. Most of the respondents (more than 75%) were between 26 and 55 years old, and almost all of them (95.4%) had completed their college education. Since the survey was deployed to "construction experts" from professional organizations and academia, laborers were not included. Superintendents and foremen were included because it is necessary to have a college degree (in architecture or engineering) to work as a superintendent or foreman in Ecuador. The great majority of the respondents (80.1%) had a degree in engineering, while architects and contractors accounted for 17.5% of the respondents. Around 81 % of the respondents had more than 5 years of experience in the construction industry and 69.8% of all the construction experts had their main field of expertise focused on construction. Also, 65.4% of all respondents worked on constructing buildings and houses. As can be inferred from the descriptors of the sample, the respondents had important expertise regarding the use of concrete as a construction material in building and housing projects, and transportation and hydraulic facilities.

For each of the factors in Table 2, respondents provided their perception of the impacts of unstructured factors on compressive strength, cost and production rates, using the following Likert scale: (1) no impact, (2) very low impact, (3) low impact, (4) medium impact, (5) high impact and (6) very high impact.

Data Analysis

RII was used to identify and evaluate the importance of the unstructured factors. Tests for equality of odds were performed by using Likert response aggregation to understand the influence of the respondents' characteristics on their perceptions of the impact of unstructured factors on concrete [37]. The data collected will provide additional information about current practices and mitigation actions for future studies.

Relative Importance Index (RII)

RII can be applied for ranking construction-related affecting factors when using a Likert- type scale [29-36], A six-point scale ranging from I (None) to 6 (Very High) was adopted to determine the impact of unstructured factors on compressive strength, costs and production rates. RII ranges from 0 to I and is calculated as in Ec. 1, where is the weighting given to each factor by the respondents (1 to 6), is the highest weight (i.e., 6) and is the total number of respondents. The higher the RII, the higher the ranking and the perceived importance of the affecting factor.

Likert Response Aggregation

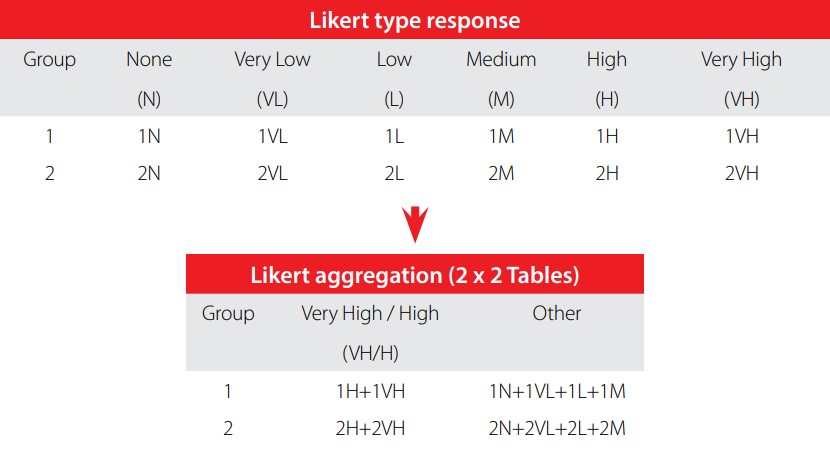

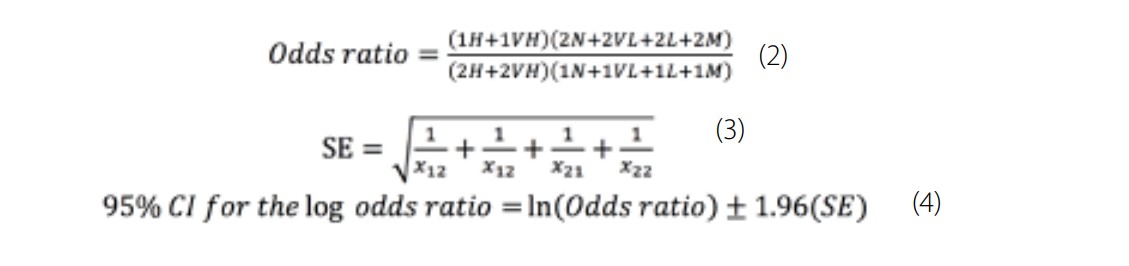

Siegel and Castellan [37] suggested a procedure for aggregating Likert-type responses into only two values, allowing us to build up data for comparing the responses of two groups of participants with different characteristics [17], In this way, construction experts' agreement to a particular state (e.g., high and very high impact) could be separated from others. The Likert aggregation process is illustrated in Fig. 3. It consists of adding together the responses with very high (VH) and high (H) impacts as well as the responses with None (N), Very Low (VL), Low (L) and Medium (M) impacts in order to compile each Likert response into only two values: (VH+H) and (N+L+VL+M).This approach was used because the intent was only to study factors perceived to affect concrete highly (VH+H).

Likert response aggregation process

Tests for Equality of Odds

Contingency tables (2x2 tables) containing the responses of two categorical variables are appropriate instruments to explore the relationship between two categorical variables with natural ordering [38] and are used for performing chi-square tests of association between variables (two way tables). This test for equality of odds allows us to compare two different groups and determine if a response differs regarding the same question. The odds ratio is then used to compare the effect of each level of a categorical variable on the estimated probability. Ramsey and Schafer [39] described shortcut methods for estimating the odds ratio in such a table and the corresponding confidence interval. The odds ratio is computed as the ratio of the products of the main diagonals of the 2x2 table as shown in Ec. 2, and the confidence interval (Cl) is calculated by using a shortcut method for the standard error (SE) of the log odds ratio. SE is the square root of the summation of the four reciprocals of a 2x2 table (Ec. 3) and the 95% Cl is obtained from the antilogarithm of the end points of the 95% Cl for the log odds ratio (Ec. 4).

RESULTS

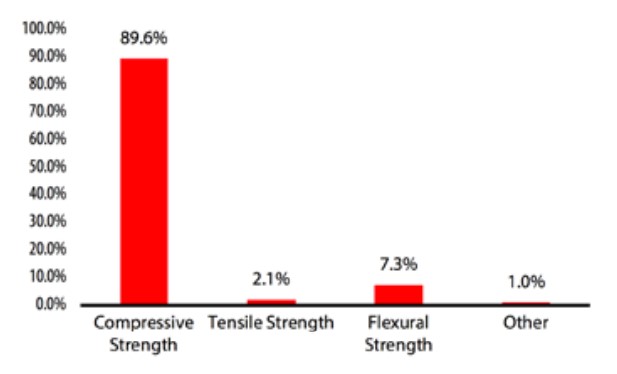

Concrete Quality Metric

The results indicated that concrete compressive strength is the metric used by most of the respondents (89.6%) for measuring concrete quality (Fig. 4) regardless of the type of facility or application, which is an expected result, confirming findings from the literature search. Thus, compressive strength is an appropriate quality metric to use in this study.

Concrete quality metric

Perceived Importance of Unstructured Factors

As previously mentioned, survey respondents were asked to assess the importance of unstructured factors identified in Table 2 considering their perceived degree of impact on concrete compressive strength, costs and production rates through a Likert type scale. Importance indexes for each affecting factor, computed by using Ec. 1, were employed to evaluate the perceived importance of the unstructured factors and to establish the ranking of the unstructured factors.

Table 3 comprises RI 1 values for each identified affecting factor, allowing us to establish lists of affecting factors in descending order. The numbers in parentheses represent the corresponding importance, with I being the most important. Thus, the higher the RII, the higher the importance.

Curing humidity, crew experience and compaction are the top three factors affecting concrete compressive strength according to the respondents (Table 3). Regarding concrete costs and production rates, crew experience, mixing time and compaction lead the ranking list of the unstructured factors affecting concrete. Notice that crew experience and compaction are common perceived factors that greatly influence concrete, revealing that construction experts are aware that the use of qualified workers and appropriate equipment are crucial to concrete fabrication. Also, almost all respondents indicated that unstructured factors do affect concrete costs somehow. Only a very small percentage (1.9%) stated that unstructured factors do not have any effect on concrete cost. In addition, experts pointed out that curing conditions, mixing time and compaction should be paid special attention to ensure concrete quality and meet budget specifications (i.e., costs and production).

A global ranking of importance for the identified unstructured factors was calculated by compiling all responses (Table 4), giving the same weight for compressive strength, costs and production rates. Crew experience, compaction and mixing time are found to be the top three affecting factors perceived to influence concrete during the construction process. On the other hand, adding extra water (via rain) and ambient temperature are perceived to be the least affecting conditions when performing concrete operations.

Although the differences in the results for Rlls are small as it can be seen from Table 3 and Table 4, RII is the accepted methodology to rank the unstructured factors identified in the literature based on their mathematical values. If significant difference in the response is desired, statistical hypothesis testing should be carried out.

| Number | Identified Factor | R" 1 | ||

| Compressive strength as a quality metric | Costs | Production | ||

| 1 | Mixing time | 0.722 (6) | 0.649 (3) | 0.682 (2) |

| 2 | Compaction | 0.753 (3) | 0.654 (2) | 0.649 (3) |

| 3 | Ambient temperature | 0.686 (7) | 0.534 (6) | 0.616(5) |

| 4 | Curing temperature | 0.746 (4) | 0.634 (5) | 0.559 (7) |

Impact of unstructured factors on concrete compressive strength, costs and production

| 5 | Curing humidity | 0.792 (1) | 0.635 (4) | 0.612(6) |

| 6 | Adding extra water | 0.743 (5) | 0.514(7) | 0.637 (4) |

| 7 | Crew experience | 0.781 (2) | 0.765 (1) | 0.763(1) |

Impact of unstructured factors on concrete compressive strength, costs and production

| Rank | Identified Factors | RII |

| 1 | Crew experience | 0.7695 |

| 2 | Compaction | 0.6854 |

| 3 | Mixing time | 0.6846 |

| 4 | Curing humidity | 0.6798 |

| 5 | Curing temperature | 0.6465 |

| 6 | Adding extra water | 0.6315 |

| 7 | Ambient temperature | 0.6120 |

Overall ranking importance of identified unstructured factors for concrete compressive strength, costs and production

Comparison of Responses by Group

Architects and engineers accounted for 94.6% of the respondents. Chi-square tests of association between variables using 2x2 tables (Fig. 3) and Ramsey and Schafer [39] shortcut methods for estimating odds ratios and confidence intervals were utilized to analyze the data. A summary of the odd ratios, confidence intervals and p values for the perceptions of architects (Group 1) and engineers (Group 2) regarding the impact of identified unstructured factors on concrete strength, cost and production rates is presented in Table 5.

As shown in Table 5, with respect to mixing time, architects were 2.59, 2.93 and 3.60 times more likely than engineers to perceive a very high or high impact of mixing time on concrete strength, cost and production rates. In all cases the p values (0.009, 0.001 and 0.000) are less than 0.05. For ambient temperature, for example, p values for the impact on concrete strength and costs are greater than 0.05, indicating that there is not enough evidence that the odds ratio differs from 1, and thus no conclusion can be inferred from such comparisons in this case. Therefore, for all odds ratios that are greater than 1 and p values less than 0.05, it can be inferred that architects are more likely to perceive high or very high impacts of such unstructured factors on concrete than engineers do.

In practice, the aforementioned results are of importance to construction practitioners since architects were found to be the technicians who are more likely to ring the bell about the potential impact of unstructured factors on concrete when fabricating concrete In-situ. However, this does not mean that engineers are not able to identify such impacts. Engineers do recognize and warn such adverse conditions but perceive them with less impact. The results shown in Table 5 simply point out the perception of architects and engineers regarding several concrete affecting conditions. The difference in perception between architects and engineers suggests that the characteristics of a group such as profession may determine their response.

| Impact | Odds Ratio | 95% Cl | p value | |

| Mixing Time | ||||

| Strength | 2.59 | 1.25 | 5.37 | 0.009 |

| Cost | 2.93 | 1.50 | 5.74 | 0.001 |

| Production | 3.60 | 1.78 | 7.25 | 0.000 |

| Crew Experience | ||||

| Strength | 2.60 | 1.19 | 5.66 | 0.014 |

| Cost | 3.14 | 1.44 | 6.83 | 0.003 |

| Production | 4.09 | 1.82 | 9.19 | 0.000 |

| Compaction | ||||

| Strength | 3.25 | 1.49 | 7.07 | 0.002 |

| Cost | 3.66 | 1.84 | 7.30 | 0.000 |

| Production | 4.83 | 2.38 | 9.77 | 0.000 |

| Curing Temperature | ||||

| Strength | 2.50 | 1.20 | 5.19 | 0.012 |

| Cost | 3.97 | 2.02 | 7.82 | 0.000 |

| Production | 0.80 | 0.36 | 1.77 | 0.587 |

| Curing Humidity | ||||

| Strength | 2.55 | 1.17 | 5.57 | 0.015 |

| Cost | 4.25 | 2.13 | 8.50 | 0.000 |

| Production | 0.59 | 0.27 | 1.29 | 0.179 |

| Adding Extra Water | ||||

| Strength | 2.98 | 1.41 | 6.33 | 0.003 |

| Cost | 0.72 | 0.33 | 1.58 | 0.412 |

| Production | 5.43 | 2.68 | 11.01 | 0.000 |

| Ambient Temperature | ||||

| Strength | 1.85 | 0.96 | 3.58 | 0.064 |

| Cost | 0.60 | 0.25 | 1.43 | 0.247 |

| Production | 2.60 | 1.34 | 5.03 | 0.004 |

Comparison of responses by architects and engineers regarding the impact of unstructured factors on concrete strength, costs and production

Identification of Additional Unstructured Factors

In addition to the unstructured factors identified in the literature and shown in Table 2, construction experts were asked to identify additional unstructured factors recognized throughout their careers. Only 23% of the respondents provided additional factors. They are listed in Table 6 and categorized into workforce, machinery and equipment, jobsite environment and concrete fabrication process. These additional factors are of importance for construction practice since they provide construction practitioners with more information tending to reduce uncertainties when fabricating concrete, facilitating the decision making process. Thus actions tending to preserve concrete product could be made on time, avoiding delays and cost overruns.

Additionally, a recommendation for further research is given in the corresponding section since including these factors on a new survey could influence the results; however, the authors believe that the results would not change significantly.

| Workers | Machinery and Equipment | Jobsite Environment | Concrete Fabrication Process |

| • Deficient formwork | •The use of proper | • Contaminated | •Time of concrete |

| • Mixing wrong material | tools when dealing | concrete materials | fabrication |

| guantities | with concrete | (water and aggregates) | •Time of concrete |

| • Excess of admixtures • Height of concrete pouring (segregation) •Concrete volume to be made • Type of concrete element to be fabricated | • Means of concrete transportation | •Wind (fast dry of concrete) •Vibrations after concrete setting •Nighttime construction •Aggressive environment (soil - fou ndations) | placement |

Additional unstructured factors identified by the respondents

Current Practices and Mitigation Actions

Research results show that a significant percentage of construction experts (57.6%) are aware of the presence of unstructured factors during concrete operations, and some preventive actions are carried out to minimize their effects on concrete. When comparing the responses of the two major groups - architects and engineers - regarding the awareness of the existence of unstructured factors by using 2x2 tables, it can be concluded that there is not enough evidence that the odds ratio differs from 1 regarding previous knowledge of such factors. Also, construction experts who are aware of unstructured factors tend to take some mitigation actions during concrete operations.

For example, to prevent the addition of extra water to fresh concrete, the concrete is protected from rain by either avoiding concrete fabrication on rainy days or by using plastic protection. In addition, the use of experienced crews is preferred for concrete production. Survey results suggest that the use of experienced crews when fabricating concrete is preferred to reach concrete compressive strength. A very high percentage of construction experts (91.3%) have utilized experienced crews when dealing with concrete. Regarding curing conditions, 80.9% of respondents did not consider temperature when curing concrete. The only concern was keeping concrete wet (i.e., preserving humidity) due to the difficulty of providing such a controlled environment on the jobsite, and the costs associated with this activity.

Moreover, 28 days is thought to be the period of time necessary for concrete to reach its design capacity by the majority of construction experts (79.1%), which is in agreement with standard acceptance tests; namely, ASTM standards C31 [40] and C39 [41] and the requirements established by The American Concrete Institute [42], Concrete design strength at the age of 28 days is well known for a construction expert; however, other group of experts believe that less time is necessary when using admixtures or another type of cement.

Even though concrete should not be fabricated in situ due to quality control aspects when fabricated manually, the results indicate that significant amounts of concrete are actually made on the jobsite. Seventy-six percent of the respondents believed that more than 10% of concrete required for a facility is fabricated in situ; they recommended the use of concrete mixers to ensure all ingredients are mixed uniformly. The high percentage of concrete made on the jobsite could be explained due to the perception that ready-mixed concrete is more expensive than concrete fabricated in situ, even though the difference is not that large. This statement should be valid or applicable to developing countries. Although the cost of ready mixed concrete is usually higher than on site mixed concrete, this difference of costs is commonly compensated by the cost of supervisory staff, site organization and amount of cement utilized [1],

Although construction experts accepted that significant amounts of concrete are made on the jobsite, they were aware that concrete quality may be compromised. Most respondents (89.0%) believed that concrete fabricated in a plant (i.e, ready-mixed) and on the jobsite (either mixed by hand or using a concrete mixer) do not have the same quality.

DISCUSSION

In this study, unstructured factors affecting quality (as measured by compressive strength), costs and production rates have been identified in the literature and through the perceptions of construction experts, using a survey instrument. The majority of the participants were Ecuadorians. With respect to concrete compressive strength, curing humidity (RII=0.792), crew experience (RII=0.781) and compaction (RII=0.753) are the top three affecting construction site factors, followed by curing temperature (RII=0.746), adding extra water (e.g, rain) (RII=0.743), mixing time (RII=0.722) and ambient temperature (RII=0.686). Even though the majority of construction experts were aware of the existence of such factors, most of them did not report taking preventive actions to minimize the effects of the factors on concrete. For instance, 80.9% of respondents did not consider curing temperature when curing concrete. However, concreting when raining (which could add extra water to fresh concrete mixtures) was one factor considered during concrete operations by protecting fresh concrete from rain.

In terms of costs, the respondents believed that crew experience (RII=0.765), compaction (RII=0.654) and mixing time (RII=0.649) are the most important factors that affect concrete. Also, construction experts recognized that curing conditions have an important impact on costs, suggesting that taking no mitigation actions against such factors could be due to the significant increase in concrete costs. With respect to production rates, construction experts believed that crew experience (RII=0. 0.763), mixing time (RII=0.682) and compaction (RII=0.649) control concrete productivity, agreeing with the saying “time is money”. The more resources, the more expensive.

When considering an overall ranking of affecting factors for concrete compressive strength, costs and production, crew experience (RII=0.7695) comes first, followed by compaction (RII=0.6854) and mixing time (RII=0.6846). The least perceived affecting factors are adding extra water (RII=0.6315) and ambient temperature (RII=0.6120). These global rankings were computed by giving the same weight or importance to compressive strength, costs and production.

In addition to the previous unstructured factors, a small group of construction experts identified other important unstructured factors recognized throughout their careers that may also affect concrete compressive strength, costs and production rates. Such factors were classified according to their source and included deficient formwork, nighttime construction and the use of improper tools when dealing with concrete. These factors should be investigated in future research.

Moreover, the use of 2x2 contingency tables and tests for equality of odds allowed us to understand how profession (being an architect or engineer) can influence respondents' perceptions about the impact of unstructured factors on particular concrete characteristics.

When comparing the two main groups of respondents - architects and engineers - regarding their perceptions of the effect of unstructured factors on concrete compressive strength, costs and production rates, the results indicate that architects are more likely to perceive high or very high impacts than engineers do when judging the effect of an unstructured factor.

Several recommendations for practice based on the results of this study can be given. Concrete practitioners should take into account several unstructured or construction site factors when performing concrete operations at the jobsite in order to prevent concrete product from undesired impacts. The perceived importance of construction- related factors that affect concrete provide practitioners with valuable information so that mitigation actions could be made. The less uncertainty in the information about affecting concrete conditions, the more the chances are for producing concrete having expected characteristics in situ. Also, knowing how construction experts' characteristics (i.e., architects and engineers) influence their perceptions of these factors may assist construction practitioners on the decision making process. Being aware of the effect of the factors that were not considered before can indeed help not only take correction actions to preserve concrete product but also save time and money.

To sum up, unstructured factors should be considered and monitored during concrete fabrication while the construction phase of a facility. This will help ensure that concrete complies with design specifications established in the construction documents. However, additional research is needed to quantify the impact of these factors on concrete.

Even though the population sample was large enough to ensure a high level of confidence in the results in Ecuador, we expected to have similar numbers of construction experts (the sample population) belonging to each of the following groups: architects, engineers, and contractors; in reality, only two major groups – architects and engineers – accounted for 94.6% of the survey sample. Also, architects and engineers were not equally represented. However, most respondents surveyed (80.7%) had more than 5 years of experience in the construction industry and around 92% had experience constructing buildings, houses, transportation and hydraulic facilities.

A major limitation could be that the majority of the respondents belonged to Ecuador, a Latin American developing country, where construction practices may not be similar to those utilized in developed countries. Nonetheless, the concrete code in Ecuador was developed based on the American Concrete Institute principles.

The results revealed that more than 10% of concrete is fabricated on the jobsite; hence it is necessary to investigate how to quantify the effects of construction site factors not only on compressive strength as a concrete quality metric, but also on costs and production rates. Employing inexperienced crews for concrete fabrication, for instance, may increase concrete unit prices by increasing the time needed for performing an activity, diminishing production rates. However, there are some potential challenges and aspects that must be considered when carrying out this proposed research. The method or technique chosen to achieve that goal will depend on the availability of appropriate equipment and laboratories that guarantee the replication of the aforementioned affecting conditions, so that the effect of unstructured factors may be measured reliably.

Furthermore, additional unstructured factors identified by construction experts throughout their careers should be considered in future studies, to identify and evaluate the perceived importance of such additional construction-related factors that affect concrete by construction experts. Lastly, other quality metrics, methods or procedures such as concrete aesthetics should be explored not only for the identification and ranking of unstructured factors but also to study the effect of construction experts' characteristics on their responses.

References

Neville, A. M. & Brooks, J. J. (2010). Concrete Technology (2nd ed.), Prentice Hall, Harlow, England.

Okasha, N. M. & Aichouni, M. (2015). Proposed structural reliability-based approach for the classification of concrete quality. Journal of Materials in Civil Engineering, 27(5), 04014169, doi: https://doi.org/10.1061/(ASCE)MT.1943- 5533.0001131

Portland Cement Association (2015). Cement & concrete applications: Products, available at http://www.cement.org/cement-concrete-basics/product! (accessed 17 February 2016).

Kosmatka, S. H., Kerkhoff, B. & Panarese, W. C. (2002). Design and Control of Concrete Mixtures (14th ed.), Portland Cement Association, Skokie, III.

Mehta, P. K. & Monteiro, P. J. M. (2006). Concrete: Microstructure, Properties, and Materials (3rd ed.), McGraw-Hill, New York, NY.

Demirboga, R., Orting, I. & Gül, R. (2001). Effects of expanded perlite aggregate and mineral admixtures on the compressive strength of low-density concretes. Cement and Concrete Research, 31(11), 1627-1632.

Jongpradist, R, Jumlongrach, N., Youwai, S. & Chucheepsakul, S. (2010). Influence of fly ash on unconfined compressive strength of cement-admixed clay at high water content. Journal of Materials in Civil Engineering, 22(1), 49-58, doi: https://doi.org/10.1061/(ASCE)0899-1561(2010)22:1(49)

O'Connor, J. T. & Huh, Y. (2006). Crew production rates for contract time estimation: Beam erection, deck, and rail of highway bridges. Journal of Construction Engineering and Management, 132(4), 408-415, doi: https://doi.org/10.1061/(ASCE)0733-9364(2006)132:4(408)

Jarkas, A. M. (2010). Analysis and measurement of buildability factors affecting edge formwork. Journal of Engineering Scienceand Technology Review, 3(1), 142-150.

Jarkas, A. M. (2012). Buildability factors influencing concreting labor productivity. Journal of Construction Engineering and Management, 138(1), 89-97, doi: https://doi.org/10.1061/(ASCE)CO.1943-7862.0000404

Heravi, G. & Eslamdoost, E. (2015). Applying artificial neural networksfor measuring and predicting construction-labor productivity. Journal of Construction Engineering and Management, 141 (10), 04015032, doi: https://doi.org/10.1061/(ASCE)C0.1943-7862.0001006

Yuan, Z., Wang, L.N. & Ji, X. (2014). Prediction of concrete compressive strength: Research on hybrid models genetic based algorithms and ANFIS. Advances in Engineering Software, 67, 156-163, doi: http://dx.doi.org/10.1016/].advengsoft.2013.09.004

Rodríguez-Garzón, I., Martínez-Fiestas, M., Delgado-Padial, A. & Lucas-Ruiz, V. (2016). An exploratory analysis of perceived risk among construction workers in three Spanish-speaking countries. Journal of Construction Engineering and Management, 142(11), 04016066, doi: https://doi.org/10.1061/(ASCE)C0.1943-7862.0001187

Dai, J., Goodrum, P. M. & Maloney, W. F. (2009). Construction craft workers' perceptions of the factors affecting their productivity. Journal of Construction Engineering & Management, 135(3), 217-226, doi: https://doi.org/10.1061/(ASCE)0733-9364(2009)135:3(217)

Lu, S. &Yan, H. (2013). A comparative study of the measurements of perceived risk among contractors in China. International Journal of Project Management, 31(2), 307-312.

Zhang, P., Lingard, H., Blismas, N., Wakefield, R. & Kleiner, B. (2015). Work-health and safety-risk perceptions of construction-industry stakeholders using photograph-based Q methodology. Journal of Construction Engineering & Management, 141 (5), 04014093, doi: https://doi.org/10.1061/(ASCE)CO.1943-7862.0000954

Tymvios, N. & Gambatese, J. A. (2016). Perceptions about design for construction worker safety: Viewpoints from contractors, designers, and university facility owners. Journal of Construction Engineering and Management, 142(2), 04015078, doi: https://doi.org/10.1061/(ASCE)C0.1943-7862.0001067

Heeringa, S., West, B.T. & Berglund, P. A. (2010). Applied Survey Data Analysis, Chapman & Ha ll/CRC, Boca Raton, FL.

Laungrungrong, B., Mobasher, B., Montgomery, D. & Borrar, C. M. (2010). Hybrid control charts for active control and monitoring of concrete strength. Journal of Materials in Civil Engineering, 22(1), 77-87, doi: https://doi.org/10.1061/(ASCE)0899-1561(2010)22:1(77)

Wight, J. K., Richart, F. E. & MacGregor, J. G. (2012). Reinforced Concrete: Mechanics and Design (6th ed.), Pearson Prentice Hall, Upper Saddle River, NJ.

Li, Z. (2011). Advanced Concrete Technology, Wiley, Hoboken, NJ., Hassoun, M. N. & Al-Manaseer, A. A. (2012). Structural Concrete: Theory and Design (5th ed.), Wiley, Hoboken, NJ.

Unanwa, C. & Mahan, M. (2014). Statistical analysis of concrete compressive strengths for California highway bridges. Journal of Performance of Constructed Facilities, 28(1), 157-167, doi: https://doi.org/10.1061/(ASCE)CF.1943-5509.0000404

Chen, X., Wu, S. & Zhou, J. (2014). Variability of compressive strength of concrete cores. Journal of Performance of Constructed Facilities, 28(4), 06014001, doi: https://doi.org/10.1061/(ASCE)CF.1943-5509.0000513

Sears, S. K., Sears, G. A., Clough, R. H., Rounds, J. L. & Segner, R. 0. (2015). Construction Project Management: A Practical Guide to Field Construction Management (Sixth ed.), Wiley, Hoboken, NJ.

Day, K. W. (1995). Concrete Mix Design, Quality Control and Specification, E & FN Spon, London, England.

Groves, R. M., Fowler, F. J., Couper, M. P, Lepkowski, J. M., Singer, E. & Tourangeau, R. (2004). Survey Methodology, Wiley, Hoboken, NJ.

Chambers, R. L. & Skinner, C. J. (2003). Analysis of Survey Data, John Wiley & Sons, Chichester, England.

Davies R. & Harty, C. (2013). Implementing site BIM: A case study of ICT innovation on a large hospital project. AUTCON Automation in Construction, 30,15-24.

El-Gohary, K. M.&Aziz, R. F. (2014). Factors influencing construction labor productivity in hy/pt. Journal of Management in Engineering, 30(1), 1-9, doi: https://doi.org/10.1061/(ASCE)ME.1943-5479.0000168

Gündüz, M., Nielsen, Y. & Özdemir, M. (2013). Quantification of delay factors using the relative importance index method for construction projects in Turkey. Journal of Management in Engineering, 29(2), 133-139, doi: https://doi.org/10.1061/(ASCE)ME.1943-5479.0000129

Gunduz, M., Nielsen, Y. & Özdemir, M. (2015). Fuzzy assessment model to estimate the probability of delay in Turkish construction projects. Journal of Management in Engineering, 31 (4), 04014055, doi: https://doi.org/10.1061/(ASCE)ME.1943-5479.0000261

Jin, R., Hancock, C, Tang, L., Chen, C, Wanatowski, D. &Yang, L. (2017). Empirical study of BIM implementation-based perceptions among Chinese practitioners. Journal of Management in Engineering, 33(5), 04017025, doi: https://doi.org/10.1061/(A5CE)ME.1943-5479.0000538

Kometa, S., Olomalaiye, P. & Harris, F. (1994). Attributes of UK construction clients influencing project consultants' performance. Construction Management and Economics, 12(5), 433-443.

Odusami, K.T. (2002). Perceptions of construction professionals concerning important skills of effective project leaders. Journal of Management in Engineering, 18(2), 61-67, doi: https://doi.org/10J061/(ASCE)0742-597X(2002)18:2(61)

Sambasivan, M. & Soon, Y.W. (2007). Causesand effects of delays in Malaysian construction industry. International Journal of Project Management, 25(5), 517-526.

Siegel, S. & Castellan, N. J. (1988). Nonparametric Statistics for the Behavioral Sciences (2nd ed.), McGraw-Hill, New York, NY.

Lavra kas, P. J. (Ed.). (2008). Encyclopedia of Survey Research Methods, SAGE Publications, Thousand Oaks, Ca.

Ramsey, F. L. & Schafer, D. W. (2013). The Statistical Sleuth: A Course in Methods of Data Analysis (3rd ed.), Brooks/Cole, Cengage Learning, Boston, MA.

ASTM International (2015). ASTM C31/C31M - 15a: Standard Practice for Making and Curing Concrete Test Specimens in the Field, ASTM International, West Conshohocken, PA.

ASTM International (2016). ASTM C39/C39M - 16b: Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens, ASTM International, West Conshohocken, PA.

ACI Committee 318 (2014). Building Code Reguirements for Structural Concrete (ACI 318-14J: An ACI Standard: Commentary on Building Code Reguirements for Structural Concrete (ACI 318R-14), an ACI Report, American Concrete Institute, Farmington Hills, ML

Additional information

AUTHORS'CONTRIBUTIONS: Jorge Santamaria conceived the research,

conducted the survey, analyzed the data, interpreted the results and wrote the

document while Vanessa Valentin, as my major advisor, supervised the research,

revised the manuscript critically and collaborated with editing.