SECCIÓN C: INGENIERÍAS

Initial study on natural fibers for use in concrete mixes as a sustainable materials alternative

Initial study on natural fibers for use in concrete mixes as a sustainable materials alternative

Avances en Ciencias e Ingenierías, vol. 16, núm. 1, e3159, 2024

Universidad San Francisco de Quito

Recepción: 18 Noviembre 2023

Aprobación: 26 Febrero 2024

Abstract: Natural fibers are becoming a key point for the development of new concrete mixes because these fibers are recovered from residual biomass. In this paper, we focus on the natural fib‘ers found in the Metropolitan District of Quito, Ecuador. For this purpose, we searched for materials (fibers) available in the Chemical Engineering laboratory at Universidad San Francisco de Quito USFQ. In this paper, we analyze different literature on how the use of fibers influences the mechanical properties of concrete. Based on this analysis and the materials at the laboratory, we have developed recommendations on which natural fibers are of interest for further experimental research. Furthermore, this paper provides an understanding of how natural fibers influence the mechanical properties of concrete. It also proposes a process for the selection and study of any type of natural fiber for further replicability in mix analysis.

Keywords: circular bioeconomy, residues, cement reduction, sustainable construction.

Resumen: Las fibras naturales se están convirtiendo en un punto clave para el desarrollo de nuevas mezclas de hormigón porque estas fibras se obtienen a partir de biomasa residual.

Este artículo está enfocado en las fibras naturales que se encuentran en el Distrito Metropolitano de Quito, Ecuador. Para ello se buscaron materiales (fibras) disponibles en el laboratorio de Ingeniería Química de la Universidad San Francisco de Quito USFQ. En este artículo se analiza diferente literatura sobre cómo el uso de fibras influye en las propiedades mecánicas del hormigón. Basándonos en este análisis y en los materiales del laboratorio, hemos desarrollado recomendaciones sobre qué fibras naturales son de interés para futuras investigaciones experimentales. Además, este artículo proporciona

diferentes conceptos de cómo las fibras naturales influyen en las propiedades mecánicas del hormigón. Asimismo, se propone un proceso para la selección y estudio de cualquier tipo de fibra natural para su posterior replicabilidad en el análisis de la mezcla.

Palabras clave: bioeconomía circular, residuos, reducción de cemento, construcción sostenible.

INTRODUCTION

This paper focuses on the integration of natural fibers into concrete mixes as a means to reduce the environmental impact of concrete and promote sustainable development. The use of natural fibers aligns with the principles of the circular bioeconomy and offers advantages such as renewability. Our specific focus is on the Metropolitan District of Quito, where local bio-based materials, like industry residues, can be utilized to develop environmentally friendly concrete mixes.

The addition of natural fibers to concrete holds promises for sustainable construction practices. By leveraging the abundance of natural fibers available and processed in Quito, the region can adopt a localized approach to creating eco-friendly concrete mixes. Understanding how different natural fibers affect the mechanical properties of concrete, such as toughness (post-peak behavior), which relates to its strength towards compressive, tensile, and flexural phenomena, is essential for formulating effective and sustainable mixes.

Through a comprehensive analysis of the existing literature and a review of available natural fiber-based materials at USFQ, this paper aims to provide insights into how natural fibers influence the mechanical properties of concrete. This paper presents novelty in the fact that there are no other studies that address this topic from a sustainable perspective. The goal is to identify natural fibers with potential for further experimental research based on the available resources of the city of Quito. Additionally, the paper proposes a framework and a decision-making procedure that can be applied to other regions and cities, facilitating the selection of suitable local natural fibers for sustainable concrete construction.

METHODOLOGY

An effective analysis of the literature was possible because of well-conducted research. We used Google Scholar and academic journal sites as our main search engines to find the papers related to our scope. Initially, we had some indications to narrow and facilitate our search. For instance, we were restricted to look for studies that used fibers from natural origin, not fibers obtained artificially. To clarify, we were able to find some studies which used steel fiber residues as a replacement for cement in a concrete mix. However, this type of fiber was deemed outside of our focus and thus ruled out, given that it had no natural origin since steel is a material not found in nature. Another condition was to concentrate on papers that chiefly increased the tensile strength of concrete. We accepted studies that in general were beneficial for the mechanical properties of concrete, but we wanted to mostly highlight the increase in tensile strength. With those instructions in mind, our most used search term was “natural fibers ‘tensile strength’ of concrete”, and we were able to find the material that is described in this study. Furthermore, note that the keywords utilized included, but were not limited to, “natural

fibers”, “concrete”, “mechanical properties”, and “sustainability”. Moreover, it is important to highlight the timeframe we put into consideration. To keep the research as updated as possible, we decided to accept studies published roughly in the last 10 years. This was to work with recent investigations that reflect the current state of the industry in terms of intellectual development in this subject matter. The sole exception was a paper from 2004, but we acknowledged it as a worthy source of information to keep it.

Another crucial aspect of our research process involved a visit to the Chemical Engineering laboratory at USFQ, which we completed on 23 March 2023 at approximately 16:00. The primary purpose of our visit was to compile an inventory of the natural fibers readily available at USFQ and to gain more insight into the topic from experts in the field. We selected the USFQ laboratory due to our close collaboration with the Chemical Engineering department. This collaboration provided us with accessibility to data on the chemical characterization of materials, thereby easing the initial stages of our research for this paper. However, our choice of laboratory does not preclude us from exploring material availability in other laboratories as our investigation gains wider acceptance.

Additionally, we aimed to determine if the fibers used in the papers we found during our online research were already accessible at the laboratory. This step was crucial to minimize transportation contamination, aligning with the primary objective of our study, which is to prioritize sustainability. During our visit, we took pictures of the fibers available at the laboratory and summarized how we could connect the fibers identified in our online investigation with those at USFQ. This allowed us to effectively plan an emulation of the mixed preparations described in the papers.

Literature review – Concrete mixes with natural fibers

The integration of natural fibers and natural fine materials into concrete mixes offers a promising solution for sustainable construction and reducing the impact of concrete production. By replacing a portion of cement with natural fine materials, the carbon footprint can be decreased while the novel mixes align with the principles of the circular bioeconomy by encouraging a lower use of cement. Cement production is an important source of CO. emissions and is estimated to contribute to 5-8% of the global CO. emissions [1]. This paper focuses on researching and cataloging insights on concrete mixes with natural fibers and natural fine materials, with a specific emphasis on materials available in Ecuador and in the city of Quito.

Moreover, the use of natural fibers could potentially improve mechanical properties of concrete mixes. As concrete is strong in compression but weak in tension, additional materials are necessary to provide tensile resistance. This resistance is traditionally provided by reinforcement bars, or recently by using steel fibers [2]. Nonetheless, natural fibers could be a promising solution to increase the tensile strength and post-peak ductility. The fibers could potentially help with crack control by reducing crack width and providing a better distribution of cracks. This contribution could also improve the fatigue life of the composite material. Ultimately, natural fibers may also provide additional fire resistance just like polypropylene fibers [3], which reduce the spalling of fire-exposed concrete as the fibers melt and the open space functions as a pressure relief valve for the pore pressure that builds up in the heated concrete.

Considering the availability and environmental impact of transportation, it is crucial to prioritize locally available natural fibers in Quito. An inventory conducted at the Chemical Engineering laboratory of USFQ revealed several natural fibers and fine materials studied previously in Quito. These materials are either naturally available in Quito, processed in the industry of the city, or brought from other parts of the country. Fibers such as African palm rachis, banana rachis, and rice husk, among others, were identified as potential candidates for sustainable concrete mixes. Moreover, as these natural fibers have been used in other projects at USFQ, the chemical composition and properties are available and known. Additionally, other fibers like abaca, curaua, sisal, jute, ramie, and linen have been studied by other researchers in Quito, and these materials were identified as good candidates for use in bio-based materials [4].

Research results – Influence of natural fibers on mechanical properties

The use of natural fibers in concrete mixes represents a recent advance, with limited experiments reported in the literature. In this study, we have concentrated on references investigating the mechanical properties in comparison to a reference concrete mix without fibers.

This section discusses the different natural mixes that were analyzed. We divided the fibers into two categories: the first, fibers that were turned into ash (pozzolanic materials), and the second, fibers used in natural state. For the first category, there was a focus on rice husk ash (RHA) in conjunction with olive waste ash (OWA) [5]. Furthermore, another study suggested that RHA could be blended with seashell ash (SSA) and bamboo fiber (BF) to enhance the tensile strength of hardened concrete [6]. For the second category, a novel concrete-like material was introduced: kenaf fiber-reinforced geopolymer concrete (KFRGC) [7]. Similarly, other studies found that jute fiber (JF) enhanced concrete tensile strength [8]. Additionally, there were suggestions that spikelet (SPF) and stalk (STF) fibers that come from oil palm empty fruit bunch fiber (OPEFB) can increase the properties of cement mortar [9]. One local reference regarding the influence of natural fibers on mechanical properties was identified. Specifically, a local study in Ecuador investigated the use of African oil palm rachis and coconut bast [10]. Below, the findings of each experiment are shown in Table 1.

| Experiment | Type offiber | Materialsused | Increment in tensilestrength | Proportionoffibersinthemix |

| Hakeem et al. (2022) | Pozzolanic materials | Rice husk ash (RHA), olive waste ash (OWA) | 41.33% | 20% of cement volume replaced with RHA and an additional 5% with OWA |

| Wahyuni et al. (2014) | Pozzolanic materials | RHA and seashell ash (SSA) | 2% to 6% | Replacement of 30% by weight of original fine aggregates |

| Noor Abbas et al. (2023) | Natural state | Kenaf fiber- reinforced geopolymer concrete (KFRGC) | 20% to 27% | Incorporating 1.25% volume fraction of 30 mm long kenaf fiber, low calcium fly ash (60% of total binder), and GGBS (40% of total binder) |

| Experiment | Type offiber | Materialsused | Increment in tensilestrength | Proportionoffibersinthemix |

| Gulzar et al. (2023) | Natural state | Jute fiber (JF), superplasticizer (SP), ground granulated blast furnace slag (GGBS) | 27% | 0.5% by volume of JF, addition of SP, and 25% by volume of GGBS |

| Rama Rao & Ramakrishna (2021) | Natural state | Spikelet (SPF) and stalk (STF) fibers that come from oil palm empty fruit bunch fiber (OPEFB) | 65% to 126% with SPF and 7.5% to 60% with STF | Replace 2% of cement mass with 15 mm-long SPF or replace 3% of cement mass with 20 mm-long STF |

| Caizaguano & Terán (2020) | Natural state | African oil palm rachis (AOPR) and coconut bast (CB) | 3.67% with AOPR and 0.71% with CB | 2% of AOPR or 2% of CB in the mix |

An important aspect to consider is that the characteristics of the fibers are already studied in each article. For instance, some of the aspects provided are diameter, density, tensile strength (of the fiber alone), Young’s modulus, specific gravity, and water absorption capacity. These characteristics are clearly outlined in order to get an overview of each fiber and predict a certain behavior when mixed with concrete. Furthermore, some articles also explore ground natural products through XRD and EDX analyses to determine their chemical composition relative to cementitious materials commonly used in traditional concrete mixes like fly ash.

Research results – Available natural fibers in Quito

To find a sustainable mix design for concrete incorporating natural fibers and ash sourced from local, environmentally friendly sources, it is essential to consider products that are readily accessible within the region. The practice of importing materials from distant coastal areas is not deemed environmentally friendly, primarily due to the associated carbon footprint resulting from transportation via fossil fuel-consuming trucks. Fortunately, Ecuador’s relatively compact geographical size mitigates this concern, as the short travel distances involved in transporting fibers have a minimal impact. Nevertheless, in a concerted effort to further reduce the carbon footprint, an inventory was conducted at USFQ as previously described. With the help of Professor Lourdes Orejuela, who oversees the laboratory, we started analyzing and classifying the fibers. The professor explained to us the process that the fibers underwent in the lab. The objective was to comprehensively identify natural fibers readily available with minimal transportation requirements. These fibers were subsequently categorized into three groups: available natural fibers, accessible bio-based aggregates, and obtainable ash products suitable for use as cementitious materials.

The focus for this research was on materials already available at USFQ in the Chemical Engineering laboratory, as initial material characterization was already carried out. As such, input parameters necessary for working with these materials in concrete mixes are available or can be obtained easily through collaboration between the departments of Chemical and Civil Engineering.

The locally available fibers that could be used in concrete mixes to explore the influence on the mechanical properties are: African palm rachis, banana rachis, mango endocarp, brewer’s spent grain (BSG), rice husk, and cacao pod husk. These are shown in Figures 1 and 2.

FIGURE 1

African palm rachis banana rachis mango endocarp left to right

FIGURE 1. African palm rachis, banana rachis, mango endocarp (left to right)

FIGURE 2

BSG rice husk cacao pod husk left to right

FIGURE 2. BSG, rice husk, cacao pod husk (left to right)

Potential bio-based aggregates locally available are quinoa residue, banana biochar, rose plantation residue, and hydrochar made from mango endocarp, rice husk, blackberry residue, moringa peel, and cacao pod. For instance, these raw materials can be of great use for nanocellulose which produces so-called smart materials [11]. In turn, nanocellulose can be implemented in concrete mixes for improved physical and mechanical properties as well as self-healing abilities. In terms of bio-based ash products that can be used as a supplementary cementitious material, rice husk can be

used to make rice husk ash. The materials available at USFQ at the moment of doing the inventory are shown in Figure 3.

FIGURE 3

Banana biochar rose plantation residue mango endocarp hydrochar left to right

FIGURE 3. Banana biochar, rose plantation residue, mango endocarp hydrochar (left to right)

As can be noted, some of these available fibers have a connection with the literature review presented, and some of the fibers in the inventory are new in relation to the contents of the review. Therefore, as of now, we will select two fibers to elaborate on as they present the greatest potential for future investigation at USFQ. Specifically, we will select rice husk with the use of Hakeem et al. and Wahyuni et al. as references for mixing, and African palm rachis with Caizaguano and Terán as a guidance on the trial mix design.

Specifically, RHA should be prepared at a target temperature of 600 °C that should be reached at a rate of 10 °C/min and then maintained for 2 hours. Then, the RHA should be cooled at 1.67 °C/min with an additional cooling in air at room temperature for 35 min. Lastly, a screening of the RHA is to be performed with a 75 μm sieve before mixing with concrete [5]. It is important that the material is stored in airtight bags for storage purposes. To complement the previous guidance, the water binder ratio should be kept at 0.45, and the slump value should equal approximately 6 to 10 cm [6].

On the other hand, the methodology for preparing African palm rachis involves a chemical treatment. Specifically, the treatment is based on a water solution mixed with 10 g of lime hydroxide per liter of water. The fibers should be placed inside the solution for 48 hours, then washed with clean water and checked to see if the water comes out clear. If it does not, the process should be repeated as many times as needed until the water comes out clear. Afterwards, these fibers are cut at a length of 38 mm to then be placed in the concrete mix [10].

The other natural fibers available at USFQ are not discarded from this study and represent a good starting point for new, locally relevant research that will broaden the perspective of materials about which information in literature can be found. For these materials, additional characterization of the fiber properties may be necessary as a basis for the research.

Recommendations for fiber selection

The experience presented in this paper can serve as a basis for other cities and regions where there may be an interest in locally developing concrete mixes with natural fibers and products as part of the transition to the circular economy. From our pilot study, we can give the following recommendations as a framework for those who may want to apply our strategy:

• Prioritize locally available natural fibers to support the concept of the circular economy and reduce carbon emissions associated with transportation.

• Prioritize fibers that result from existing industries, like banana rachis residues from local snack producers, and give preference to natural fibers with low embodied energy, renewable sourcing, biodegradability, and potential for waste valorization to minimize the carbon footprint of concrete and promote sustainability.

• Assess fiber characteristics by evaluating the physical and mechanical properties of natural fibers, such as length, diameter, strength, elasticity, moisture content, absorption, and degradation in an alkaline environment to ensure their suitability for concrete mixes.

• Evaluate the fiber performance in concrete by examining the influence of natural fibers on the concrete’s mechanical properties, including compressive strength, tensile strength, modulus of elasticity, flexural strength, and durability at various points in time.

• Obtain experimental data and compare theoretical insights to better understand how different fibers perform in concrete mixes.

• Assess the practicality of sourcing and incorporating selected natural fibers in large-scale concrete production, considering their availability and cost. Evaluate their compatibility with existing supply chains in the local construction industry.

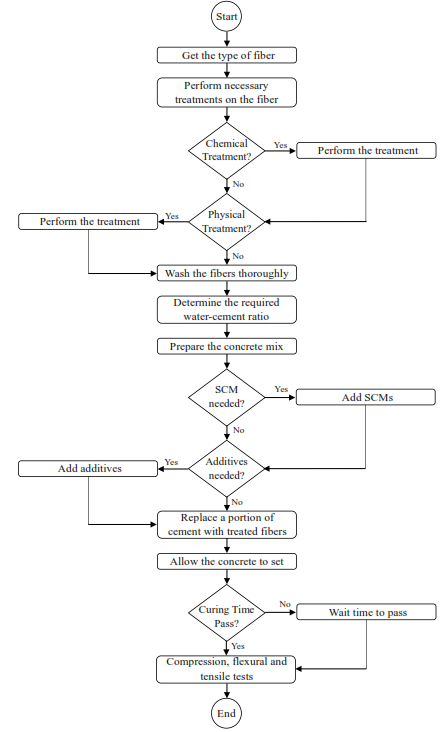

A flowchart showing the recommended steps to follow in order to prepare every type of fiber mix is shown in Figure 4. This flowchart can help researchers who are identifying available natural fibers in their location and help with the decision-making on the exploration of the natural fibers in concrete mixes. In addition, the flowchart provides the various steps that are relevant in the process of developing a mix design in which natural fibers are used to both improve the mechanical properties and replace the fine materials (cement) for a more sustainable alternative.

FIGURE 4

Concrete mixing with fibers flowchart

As explained previously, this flowchart indicates a general process for the implementation of natural fibers in concrete mixes so that the result is efficient and synonymous to that of the studies presented in this article. It is evident that each paper presented in the research results section is different in its own way, but it is possible to summarize their procedures in a flowchart such as the one in Figure 4. The flowchart starts with the obtention of the fiber in the most efficient and sustainable way, preferably if the

fiber is available locally before importing it. This aligns with the study’s aim to be as environmentally friendly as possible. Then, for every paper, the fibers are treated either in a chemical or physical manner to prepare them before including them in the mix. For instance, some fibers are placed in a lime hydroxide solution [10], which would indicate a chemical treatment. On the contrary, other fibers are cut to a determined length [8], which implies a physical treatment. Some papers include both a chemical and a physical treatment, and the chemical treatment usually comes first. Then, the general mix design is carried out by considering the water-cement ratio and whether supplementary cementitious materials (SCM) are needed according to each paper. After that comes a crucial step, which is the replacement of a percentage of cement, either by volume or by weight, with the natural fiber to be used. The replacement must be done in the percentage that each paper indicates because each fiber behaves differently and needs more or less quantity to achieve the expected results. Lastly, the appropriate tests must be conducted to evaluate the mechanical performance of the mix which should yield results nearly similar to those of the papers studied.

DISCUSSION

This paper shows the first work on developing concrete mixes using natural fibers to improve the mechanical properties of the resulting composite material and to reduce the carbon footprint by replacing part of the fine materials with natural products that may be byproducts of other industrial activities. As natural fibers are a renewable resource, the use of these materials also contributes to the shift to a circular bio-based economy.

As a first step, identifying potentially interesting materials needs to be carried out. This paper reports an initial study on natural fibers and identifies the available materials locally in Quito that could be of interest to serve as fibers in concrete mixes and to partially replace the fraction of fine materials (cement) in the mix. Then, the paper provides considerations for researchers who would want to use natural fibers available in their city, and practical guidance on working towards a mixed design with natural fibers that can be tested in the laboratory.

Indeed, testing these mixes in the laboratory is a necessary step and precisely the next step in this research. We will focus first on the use of natural fibers to provide crack bridging and improve the post-peak ductility of concrete beams tested in displacement- controlled conditions. Various natural fibers will be studied, such as rice husk and African palm rachis, which are readily available at USFQ and for which we have guidance papers as a starting point, and they will be compared to traditional polypropylene fibers for reference, as well as to a reference concrete mix without fibers.

SUMMARY AND CONCLUSIONS

This study focuses on incorporating natural fibers into concrete mixes in Quito to create sustainable alternatives for the local construction industry. By prioritizing local, bio-based materials, the aim is to reduce the carbon footprint and support the circular economy. This research examines the impact of natural fibers on concrete’s mechanical

properties based on literature. Concrete mixes that have been studied in the literature and that have resulted in improved properties as compared to the reference mix include biomaterials such as rice husk ash, olive waste ash, seashell ash, bamboo fiber, kenaf fiber-reinforced geopolymer concrete, and jute fiber. In these cases, fibers are both used for mechanical properties and ground to a fine material to replace part of the cement.

The study’s inventory of natural fibers at USFQ identifies readily available materials like African palm rachis, banana rachis, mango endocarp, and rice husk for concrete production. Experience with these materials is available in the Chemical Engineering laboratory so that in collaboration with Civil Engineering, the necessary properties for concrete mixes can be obtained.

Overall, the study emphasizes the potential of natural fibers to develop sustainable concrete mixes in Quito and beyond. By considering fiber availability, characteristics, and environmental benefits, stakeholders can make informed decisions to reduce the environmental impact of concrete and promote eco-friendlier construction practices that are aligned with the transition to a circular economy. Experimental research is necessary for the application of these mixes, and a flowchart on mix design is included to guide researchers who are working with fibers available in their country and city with the selection of the materials and procedures necessary in the laboratory. These procedures focus on working both with the fresh concrete (concrete mix) and the hardened concrete (for determination of the mechanical properties).

Ultimately, there is a need for a shift from single-use natural resources that cannot be replaced to renewable natural resources. This need drives changes in the construction industry and in the way concrete mixes will be designed in the future.

REFERENCES

[1] He, Z., Zhu, X., Wang, J., Mu, M. & Wang, Y. (2019). Comparison of CO2 emissions from OPC and Recycled Cement Production. Construction and Building Materials, 211, 965–973. doi: https://doi.org/10.1016/j. conbuildmat.2019.03.289

[2] Lantsoght, E. O. L. (2019). How do steel fibers improve the shear capacity of reinforced concrete beams without stirrups? Composites Part B: Engineering, 175. doi: https://doi.org/10.1016/j.compositesb.2019.107079

[3] Bilodeau, A., Kodur, V. K. R. & Hoff, G. C. (2004). Optimization of the type and amount of polypropylene fibres for preventing the spalling of lightweight concrete subjected to hydrocarbon fire. Cement and Concrete Composites, 26(2), 163-174. doi: https://doi.org/10.1016/S0958-9465(03)00085-4

[4] Guerrero, V., Dávila, J., Galeas, S., Pontón, P., Rosas, N., Sotomayor, V. & Valdivieso, C. (2011). Nuevos Materiales: Aplicaciones Estructurales e Industriales. Escuela Politécnica Nacional.

[5] Hakeem, I. Y., Agwa, I. S., Tayeh, B. A. & Abd-Elrahman, M. H. (2022). Effect of using a combination of rice husk and olive waste ashes on high-strength concrete properties. Case Studies in Construction Materials, 17. doi: https://doi. org/10.1016/j.cscm.2022.e01486

[6] Wahyuni, A. S., Supriani, F., Elhusna & Gunawan, A. (2014). The performance of concrete with rice husk ash, sea shell ash and bamboo fibre addition. Procedia Engineering, 95, 473–478. doi: https://doi.org/10.1016/j.proeng.2014.12.207

[7] Noor Abbas, A.-G., Nora Aznieta Abdul Aziz, F., Abdan, K., Azline Mohd Nasir, N. & Fahim Huseien, G. (2023). Experimental evaluation and statistical modeling of kenaf fiber-reinforced geopolymer concrete. Construction and Building Materials, 367. doi: https://doi.org/10.1016/j.conbuildmat.2022.130228

[8] Gulzar, M. A., Ali, B., Barakat, O., Azab, M., Najemalden, A. M., Salih Mohammed, A. & Alashker, Y. (2023). Influence of jute fiber on tensile, electrical, and permeability characteristics of slag concrete: A better, cheaper, and eco-friendly substitute for conventional concrete. Journal of Natural Fibers, 20(1). doi: https://doi.org/10.1080/15440478.2023.21 70947

[9] Rama Rao, P. & Ramakrishna, G. (2021). Experimental investigation on mechanical properties of oil palm empty fruit bunch fiber reinforced cement mortar. Materials Today: Proceedings, 46, 471–477. doi: https://doi.org/10.1016/j. matpr.2020.10.269

[10] Caizaguano, Ó. & Terán, G. (2020). Caracterización del hormigón con fibras naturales del raquis de la palma africana de aceite y la estopa del coco [Thesis]. Escuela Politécnica Nacional. https://bibdigital.epn.edu.ec/handle/15000/21247

[11] Orejuela-Escobar, L. M., Landázuri, A. C. & Goodell, B. (2021). Second generation biorefining in Ecuador: Circular Bioeconomy, Zero Waste Technology, Environment and Sustainable Development: The Nexus. Journal of Bioresources and Bioproducts, 6(2), 83–107. doi: https://doi.org/10.1016/j.jobab.2021.01.004