Recent advances in residual biomass conversion into bioenergy and value-added products: A review of the Ecuadorian situation

Últimos avances en la conversión de biomasa residual en energía y productos con valor agregado: Revisión de la situación ecuatoriana

ACI Avances en Ciencias e Ingenierías

Universidad San Francisco de Quito, Ecuador

Received: 10 August 2020

Accepted: 05 November 2020

Abstract: Residual biomass is a key feedstock for the production of heat and electricity, biofuels, and green chemicals. Based on results reported in the literature, Ecuador, an agriculturebased economy, has the potential of meeting its energy demands while satisfying environmental regulations, by the conversion of self-generated residual biomass. Conventional biological, chemical and thermochemical methods have been modeled and widely studied at laboratory scale for the production of biogas, bioethanol, and other solid and liquid fuels. Based on that, they could become a milestone for upcoming scaled-up applications. Moreover, recent studies, have also shown the development of new processes for the conversion of Ecuadorian biomass residues into value-added products for future applications, such as porous materials for biomedical and waste water treatment, hydrogen production, among others. This, in general, provides a revalorization cycle of current waste streams, reducing the problem of waste treatment and disposal, and aiming to introduce bio-based products for the development of a local sustainable bio-economy.

Keywords: Ecuadorian biomass, biomass residues, agroindustry, bioenergy.

Resumen: La biomasa residual es una materia prima clave para la producción de calor y electricidad, biocombustibles y productos químicos. Con base a los resultados reportados en la literatura, Ecuador, al ser una economía basada en la agricultura, tiene el potencial de satisfacer sus demandas energéticas cumpliendo con las regulaciones ambientales, mediante la conversión de biomasa residual autogenerada. En las últimas décadas, se han modelado y estudiado ampliamente métodos biológicos, químicos y termoquímicos convencionales a escala de laboratorio para la producción de biogás, bioetanol y otros combustibles sólidos y líquidos. Los cuales pueden convertirse en la piedra base para el desarrollo de aplicaciones a mayor escala. Además, estudios recientes, han mostrado también el desarrollo de nuevos procesos para la conversión de residuos de biomasa ecuatoriana en productos de valor agregado, tales como materiales porosos para tratamiento biomédico y de aguas residuales, producción de hidrógeno, entre otros. Esto, en general, proporciona un ciclo de revalorización de las corrientes de residuos actuales, reduciendo el problema del tratamiento y eliminación de residuos, con el objetivo de introducir productos para el desarrollo de una bioeconomía local sostenible.

Palabras clave: Biomasa ecuatoriana, biomasa residual, agroindustria, bioenergía.

INTRODUCTION

Fossil fuels, such as crude oil, coal and gas remain the major sources for world energy supply. Proven reserve projections show that fossil sources would certainly expire, considering the current growing consumption rate [1-3]. Thus, the existing energy supply system appears unsustainable not only due to reserves depletion, but also implementation of more rigorous mandatory environmental regulations [4; 5]. Thus, driving worldwide research efforts into renewable sources of energy for gradually replacing fossil fuels [6]. Among other alternatives, biomass used for bioenergy production is a potential candidate for partially meeting the energy demand and reaching the net zero CO2 emissions to the atmosphere [7]. However, bioenergy from first generation biomass, also used as a food source, at industrial production might accelerate deforestation and desertification, trigger possible water privation, and would considerably increase food prices [8; 9]. Thus, biomass residues, known as second generation biomass, which also include those available at farms, released in the agro-food industry, and those remaining after product use, have grown in importance for bioenergy production. Some developed countries have already established systems to use millions of tons of organic wastes from agricultural, municipal, and industrial processes [10; 11]. Meanwhile, emerging nations have not shown the same degree of development. It is estimated that about 45% of waste generated in Latin- America ends up in open-air dumps or watercourses [12-14].

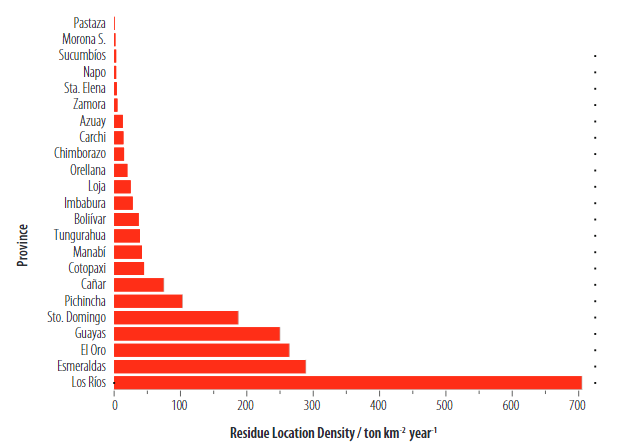

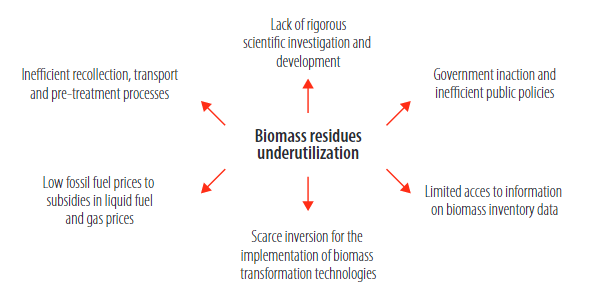

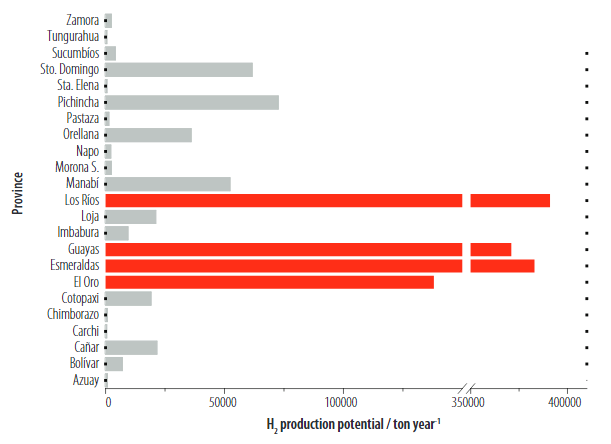

In particular, Ecuador, as many other countries in Latin-American, has an agriculture-based economy. Its geographical location provides multiple micro-climates from tropical to cold, allowing a large diversity of agricultural products. Thus, residues from agriculture, livestock farming and forestry represent important amounts of biomass. Accordingly, rice, banana, cocoa, coffee, sugarcane, maize, palm oil, plantain, pineapple, and palm heart crops represent the 84% of the total Ecuadorian agricultural production, generating about 79% of the total permanent biomass residues [15; 16]. As depicted in Figure 1, biomass residues are mainly concentrated in 5 Provinces (El Oro, Esmeraldas, Guayas, Santo Domingo) with high residue location density of approx. 200 ton km-2 year-1, and Los Ríos generating as much as 700 ton km-2 year-1. Ecuador’s potential for producing bioethanol, biodiesel, biogas or other energy carriers from biomass has been widely demonstrated. Being enough to drive the country towards the implementation of a future circular economy [17-21]. For instance, just the Ecuadorian palm oil sector generates nearly of 6.8 x 106 tons year-1 of residual biomass, which include, mesocarp fibers (3.1 x 108 kg year-1), kernel shells (KS) (1.2 x 108 kg year-1), empty fruit bunches (5 x 108 kg year-1), and field waste (5.9 x 109kg year-1) [16; 22]. (For a complete report about the Ecuadorian biomass production and potential, please refer to [16]). Even though most of the residual biomass could be used as value-added feedstock, bio-based chemical precursors or renewable energy sources, most of these residues remains underutilized. This waste can also contribute to contaminate soils and water source and the generation of greenhouse gas (GHG) emissions, due to uncontrolled degradation. As listed in Figure 2, there are several causes for biomass underutilization, according to several authors [23-25].

Ecuadorian biomass residues produced per location. Data from [15]

Major causes for biomass underutilization, according to several authors [23-25].

As already mentioned, in Ecuador, the management and use of biomass for bioenergy production is still limited [26]. For example, a recent study showed that the application of thermo-chemical processes (e.g. direct combustion, gasification coupled with gas turbine, pyrolysis, among others), just using banana residues, could provide around of 650 GWh of energy [27]. However, by 2018, sugarcane bagasse, residues from oil palm processing, and residues from the wood industry, contributed only to 1.8% (≈400 GWh) of the total nation’s electricity generation via co-generation systems [28-31]. Other initiatives, for producing ethanol, biogas, and biodiesel from sugarcane, pineapple, naranjilla (Solanum quitoense), and palm and Jatropha (Jatropha curcas) oil mills, respectively, have been developed without a considerable representation on the energy system [32-34]. Altogether, there are still scarce studies not only for bioenergy generation, but also for creating products with value-added applications.

Therefore, this contribution aims to review (see scheme in Figure 3), recent studies concerning not only the biological (anaerobic digestion, alcoholic fermentation), and thermochemicalambustion, gasification and pyrolysis) conversion of Ecuadorian residual biomass, but also the new approaches for producing value-added products for future applications. Searches were performed in a database and a search engine, such as Elsevier and Google Scholar, respectively. Eight search items were developed based on the scope of this study (e.g. “residual or recovered biomass AND Ecuador AND anaerobic digestion”). To be included, the papers had to meet a set of eligibility criteria: i) studies must have used Ecuadorian biomass, and should have been published in the last decade.

Schematic representation of the methodology followed in the short-review.

BIOLOGICAL CONVERSION

Anaerobic digestion

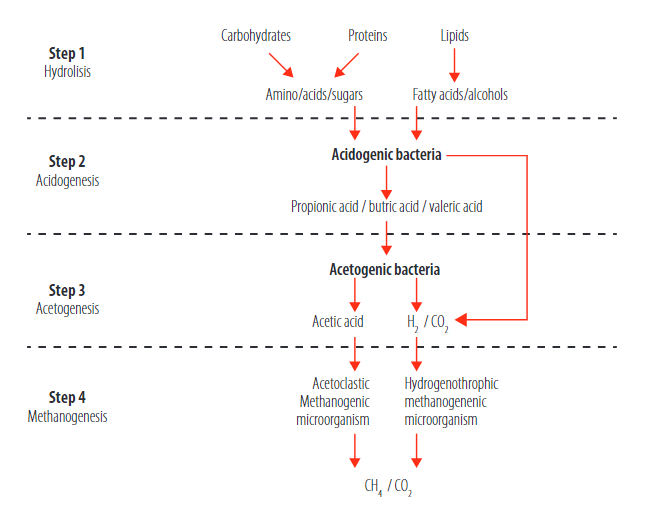

Biogas might be the most promising renewable source for addressing global energy demands and providing environmental benefits. It is a mixture of mainly methane and carbon dioxide CO2 that can be produced by anaerobic digestion (AD), which involves: i) microorganism hydroxylation of organic material into sugars, monoacids, and fatty acids under anaerobic conditions (step 1 in Figure 4), and ii) fermentation of hydrolytic products into a gas effluent (steps 2-4 in Figure 4). Benefits such as low sludge production, simple technology application and low energy consumption, make AD an efficient technology for the treatment of organic waste [35; 36]. In the Ecuadorian scenario, biological conversion can be by far, the most studied process for energy generation; however, its application has been delayed due to low-cost traditional technologies (i.e. hydroelectric power), and lack of research and economic incentives [21; 37; 38], among others.

Biological degradation steps in anaerobic digestion. Based on [51].

Lately, some efforts have been done to show the potential of anaerobic mono-and co-digestion of the organic fraction of municipal solid waste (MSW) (sediments and fruit and vegetable wastes from markets) [39-42], manure residues (e.g. bovine, pig, hen, sheep excrements) [43-46], and biomass recovered from agro-industrial wastes (blackberries, avocado, soybeas, sugarcane, cocoa, plantain, banana, among many others) [47-50]. MSW and manure residues have been commonly studied in co-digestion processes at lab-scale reactor designs, aiming to be milestones for the design and implementation of pilot-scale prototypes for energy generation in cities and small farms. Even though co-digestion shows higher biogas yield and selectivity into methane production compared with mono-digestion, further investigation is still required to understand how AD process parameters could influence the overall methane production, necessary for scaling-up projects.

In this sense, studies of mono-digestion have given insights to better understand AD process of Ecuadorian agro-industrial wastes. Almeida-Streitweiser [51] developed a complete kinetic investigation for understanding the dependency of variables, such as feed composition, fed load rate, residence time and process temperature of the rate of biomass degradation. Applying a simplified power law model, a mean reaction order of 3.7 was obtained. Interestingly, it was demonstrated that there was a different rate determining step if the system works at mesophilic (20-40 oC) or thermophilic (50-60 oC) temperatures, respectively, due to shifts in the activation energies. Furthermore, it was shown that a different biological degradation mechanism (acetoclastic or hydrogenothropic methanogenesis) governed the process, depending on the reaction temperature (see step 4 in Figure 4). In a later study, Almeida-Streitwieser and Cadena Cabezas [47], further showed the dependence of biomass composition (sugar, lipid, protein and fiber content) in relation to biogas production and quality. The highest biogas production was observed for biomass with higher protein content (soybean feedstock), while highest methane content was related to bigger amounts of fiber in the structure (sugarcane bagasse substrate). That study also showed the correlation between pH value and volatile fatty acid concentration of the reactive mixture with the biogas production and composition. Similarly, Acosta et.al [48], showed that cocoa residues, which are rich in lignin but lack of essential nutrients, could struggle to maintain the methane production (conversions up to 50% with a 60% methane content) and a balanced pH in long-term reactions. Thus, cocoa residues might need special pretreatments and the application ofco-digestion methods with nutrient-rich co-substrates in order to optimize energy production and enhance its application. Finally, biomass storage incidence, before AD, using Jatropha seed cake as feedstock, have been addressed by Gavilanes et al [49]. They showed that different times of biomass storage with water could control the amount of biogas and its quality. Jatropha cake stored for 18 months revealed to be more efficient than a cake stored for 6 months for biogas production, but with a lower selectivity towards CH4.

Alcoholic fermentation

Globally, nearly of 50% of total energy demand is consumed in the form of liquid fuels. Thus, bioethanol production has been identified as a viable short-term solution to reduce crude oil consumption and environmental pollution, as it can be used in low blends with gasoline without engine modification. Among other methods, bioethanol can be produced primarily from fermentation processes of biomass from agricultural and forestry residues with high sugar or starch contents [52; 53]. In Ecuador, residual biomasses like banana, Jatropha curcas, Andean tubers, sugarcane bagasse, pruning waste (e.g. from Ficus benjamina, Euphorbia laurifolia), and others have been lately successfully studied as feedstocks for bioethanol production [54-62]. For a complete overview of research and perspectives for second generation ethanol production from Ecuador residual biomass in earlier years, please refer to the work of Carvajal et al. [63]

Lately, some studies have assessed the potential of second generation ethanol from banana wastes [54; 55]. In the first approach, theoretical calculations were developed to estimate the conversion efficiency. Banana residues from different sources located at 440 m asl (medium-size organic banana farms) and 26 m asl (small-scale banana producers) yielded a net-energy balance of 17.1 and 7.2 MJ l-1, avoiding carbon emissions of about 0.44 and 0.34 kg l-1, respectively. These results, showed the effect of cropping at different altitudes over bioethanol generation. It has also been identified that bioethanol production from sugarcane represent a huge opportunity of development for small communities in the rural area. Velazquez-Marti et. al [56] developed a complete model to predict performance and product quality of production of bioethanol based on Brix grades during the bio-fermentation of cane juice with Saccharomyces cerevisiae. According to the authors, this prediction method could importantly reduce costs compared to common methods of control, as it is not sensor based, making the process affordable in economically depressed areas.

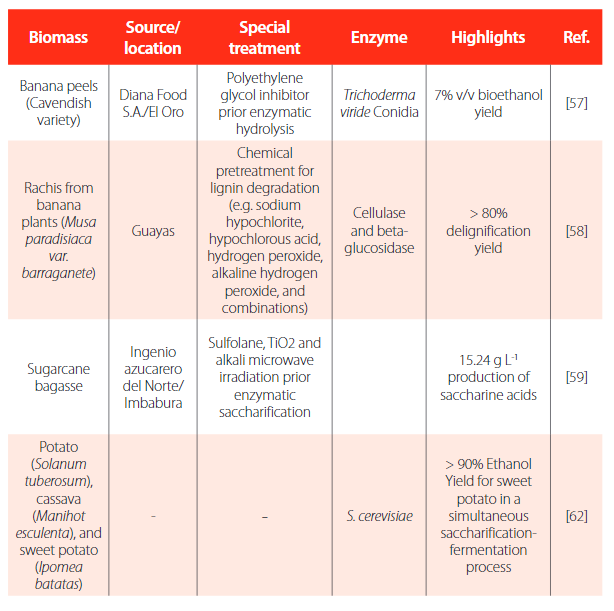

On the experimental side, a few studies have addressed the benefits of applying different biomass pre-treatments and biomass conversion methodologies (see summary in Table 1). Bonilla et al. [57], addressed a complete kinetic study for the successfully production of bioethanol (7% v/v yield) from ripe banana peels, which were discarded from the production lines of the company Diana Food S.A. in El Oro province. The kinetic study showed the positive effect of adding polyethylene glycol for degrading the inhibiting compounds present during the enzymatic (conidia ofthe Trichoderma viride fungus) hydrolysis of the substrate, before alcoholic fermentation with a commercial active dry yeast (Saccharomyces cerevisiae). Moreover, Costa et al. [58] have shown eight different chemical pretreatments for lignin degradation as alternative of physical-mechanical methods, before enzymatic saccharification of rachis from banana cultivated and collected in Guayas province. Above others, hypochlorous acid showed to be the most effective agent for lignin removal; thus, obtaining the most promising cellulose-to-glucose conversions. Portero-Barahona et al. [59] have also shown a combined pretreatment using sulfonate, TiO2 and alkali microwave irradiation for lignin degradation prior enzymatic saccharification of sugarcane bagasse obtained from a sugar production company in Imbabura. Pretreated feedstock showed an increase of the total reducing sugars and saccharinic acid production in about 5 and 33% compared to just microwave irradiation in water, respectively. Nevertheless, this process might present cost and environmental problems when used industrially. Finally, a complete study comparing the bioethanol production potential of starches from three Andean tubers (Solanum tuberosum, Manihot esculenta, lpomea batatas) has been recently released. That study showed that the starch source does not affect significantly the amount of sugars obtained after the enzymatic digestion process; thus, it does not affect the bioethanol production during fermentation. Interestingly, the simultaneous saccharification/fermentation process proved to be a more suitable process for ethanol production compared to sequential saccharification and fermentation [62].

Summary of bioethanol production studies from residual biomass applications.

THERMOCHEMICAL TRANSFORMATIONS

Thermochemical transformations can be applied to any type of biomass, including agricultural and forestry residues, by-products from the food industry, organic municipal wastes, etc. Thermochemical conversion technologies mainly include combustion, gasification and pyrolysis. During combustion, biomass (organic material) is burnt in excess air to produce heat. It is the easiest and most proven technology for power generation. However gasification, its overall heat to power efficiency is low. Gasification, on the other hand, usually occurs at high-temperature environments in the presence of oxygen or other oxidants, such as carbon dioxide or steam. It has many advantages over combustion, as it can use low-value feedstocks and convert them into electricity and transportation fuels (e.g. syngas) [64; 65]. Lastly, pyrolysis enables the production of liquid, gaseous, and solid fractions (e.g. bio-oil, pyrolysis gas, biochar) by adding heat to the feedstock in absence of oxygen. Depending on the pyrolysis and the technology applied, high thermal efficiency and low NOx, SOx, CO2 emissions can be obtained [66-68].

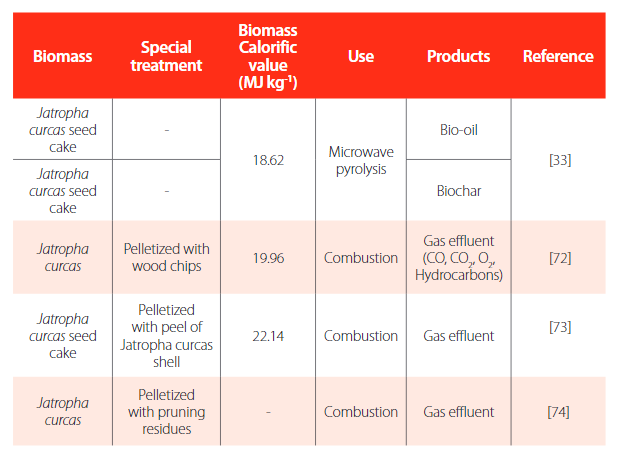

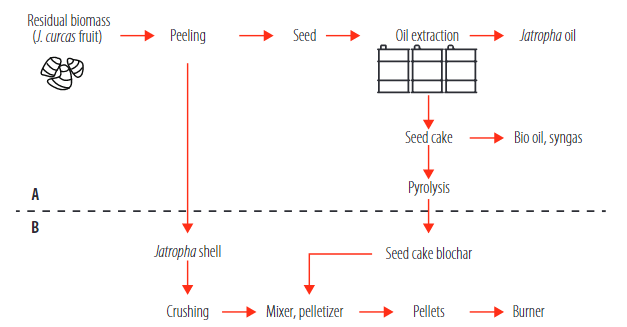

This contribution has identified several works addressing the potential of thermochemical transformations over different types of residual biomasses, such as avocado, carob (Ceratonia siliqua), mango, neem, bananas, teak pruning, and mannan-rich ivory nuts (for more information please refer to [69-71]). However, Jatropha curcas (see Table 2), and palm oil residues have received more attention. On the one hand, Jatropha curcas seed cake (JCSC) (i.e. residue from Jatropha curcas fruit oil extraction process) has been assessed as an interesting option for energy production (see process at Fig. 5a). In an early study, the obtained results from the microwave pyrolysis of JCSC indicated that the remaining organic liquid substances (bio-oil), the solid products (biochar), and the gaseous fraction are still potential energy sources that can be exploited. For instance, the liquid effluents (gross calorific value ≈) showed a maximum content of potential liquid fuel substances of around 75 %. In particular, this bio-oil might be considered as a source of liquid fuel for Otto-cycle engines. Nevertheless, it might need a distillation process to isolate the potential liquid fuels from water formed during pyrolysis, revealed by low gross calorific (3.37 MJ kg-1) and bulk density values (1.09 kg m-3). Moreover, the solid product revealed a high gross calorific value close to 28.30 MJ kg-1 that could be further applied for energy generation by combustion [33].

Summary of Jatropha curcas residual biomass applications.

In this sense, Rivadeneira et al. have pioneered the use of biochar pellets from residual biomass as combustion fuel [72; 73]. In a first approach, pellets from Jatropha curcas combined with wood chips (25-75 wt%; calorific value ≈20 MJ kg-1) were successfully tested in a small prototype horizontal burner (60 kWh) coupled to a combustion chamber. However, further investigation is needed, as CO emissions were relatively high compared to those observed during combustion of other types of biomasses in the same equipment (2.34 and 0.019 vol%, respectively). Seed cake biochar (SCB), which was obtained by the pyrolyzed residues resulting from Jatropha nut oil was combined with the peel of the fruit of the same plant (Jatropha shell (JSh)) to form pellets (see complete process in Figure 5 a and b). Those pellets were also tested in a semi-industrial continuous burner with a horizontal combustion chamber. Pellets of 4 mm particle size composed of equal amounts of JSh and SCB showed the greatest mechanical stability and higher heating values (≈ 22.14 MJ kg-1). An economic assessment for the most successful solids stated the commercial viability of this type of biochar. Their energy cost (around 0.005 USD MJ-1) represented just one third of the energy cost if using LPG for energy generation. However, according to Heredia-Salgado et al. [74], the above mentioned pellets suffered from high ash concentration content during combustion, which promoted instabilities on the flame and extinction of the combustion process within 14 minutes. Thus, in this recent publication, the authors studied a 25 wt % Jatropha curcas pellets with 75 wt % of pruning residues as more efficient fuel, which showed a stable flame and a sustained combustion process (> 60 min). Even though, the positive results, further investigation (e.g. biomass pre-treatment, better burn equipment) is still needed to improve the combustion process, and reduce the related CO emissions.

Biomass residue valorization scheme from a Jatropha oil extraction plant. a) Common process of pyrolysis of Jatropha curcas fruit residues, and b) further physical treatment (pelletization) for energy production via combustion. Based on [73].

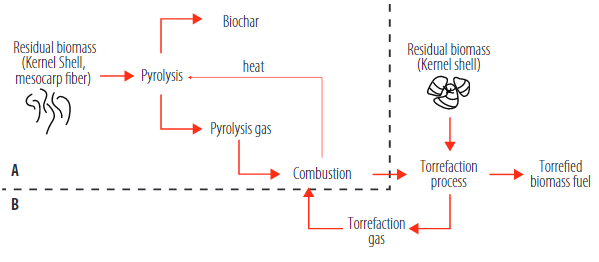

On the other side, the technical and economical utilization of Palm oil kernel shell (KS) biomass residues as solid fuels for energy purposes have also been widely addressed [22; 75]. Accordingly, it was demonstrated that the replacement of diesel by untreated KS would reduce in eight times the fuel cost of a thermal energy production in a burner, with CO gas emissions below the limits stablished by European standards (260.1 and 500 mg N-1 m-3, respectively). Moreover, if the right tax policies (e.g. non subsidies for diesel) and incentives for renewable production were implemented, associated production infrastructure would be recovered in four years. Palm oil KS biomass residues have been also studied as feedstock to produce both thermal energy and biochar (see Fig. 6a) [76]. An auto-thermal prototype modular auger reactor (i.e. neither diesel nor natural gas was used for initial heating) was used to produce macro-porous biochars with pore radius between 0.42 to 12.48 μm and ash with potential soil nutrients, such as silica, potassium, and phosphorous. Recently, KS residues have been also valorized together with mesocarp fiber, which are the most abundant residues on palm oil mill plants, in a complex pyrolysis and torrefaction combined process (see Figure 6 a and b) to produce biochar and torrefied fuel [77]. It was observed that the integrated process starts to be auto-thermal at 460 oC with an average energy efficiency of 60%. Thus, the pyrolysis and torrefaction process could represent an alternative to valorize residual biomass in the palm oil sector.

Scheme of a combined pyrolysis and torrefaction process for valorizing mesocarp fibers and kernel shell residues from a palm-oil small mill. Based on [77].

VALUE-ADDED PRODUCTS AND FUTURE APPLICATIONS

Hydrogen production

In the near future, it is expected that energy supply will be satisfied by regions with high potential for renewable generation. For instance, many research groups have shown the technical and economic feasibility of importing energy from Northern Africa to Europe [4; 78], taking advantage of the already installed fossil fuel infrastructure (e.g. ships, pipelines, gas stations) for transporting and commercializing the so-called liquid organic hydrogen carriers. Hence, the worldwide hydrogen e-fuel synthesis and use appears as the most probable solution for meeting local and global energy demands [79]. Even though no experimental methods for hydrogen synthesis could be found during the present review, a few publications have shown the Ecuadorian potential for hydrogen synthesis and energy generation from residues. According to Posso et al., municipal solid waste-derived hydrogen generation could follow two paths: i) gasification combined with steam reforming, and ii) gasification combined with electrolysis. According to the authors, being the first method the most effective, with a theoretical national production of H2 of 265,056 tons year-1. They estimated that MSW-derived H2 could satisfy public transportation energy demand in 91% of the country. In fact, the three largest urban centers (Guayas, Pichincha, Azuay), which produce around 57% of the total national MSW, could easily replace their local urban transportation diesel demand [80; 81]. In a later publication, Posso et al. [15] evaluated Ecuador’s residual biomass sources as raw material for hydrogen production, highlighting its uses not only as energy vector, but also as input in manufacturing processes (e.g. oil refining, fat hydrogenation and urea production). The total amount of possible H2 production was calculated in approx. 1.6 x 106 tons year-1 (see Figure 7), applying different conversion paths, such as gasification, combustion & electrolysis, and bio-methanization and reforming, which represented 38% of the national demand in 2017.

Hydrogen production potential from Ecuadorian biomass residues produced per location. Data from [15].

Porous materials

Porous materials have always attracted the scientific and industrial interest due to their ability to interact with atoms, ions, and molecules. Their performance on a particular application (e.g. ion exchange, adsorption (separation), catalysis) depends, to a great extent, on porosity, pore size and pore size distribution, specific surface area, and pore morphology [82]. Thus, the complete characterization and test methods used are extremely important. This work has found some scientific reports concerning the use of residual and yeast biomass as adsorbents for waste water remediation, and scaffolds for potential biomedical applications.

Wastewater remediation

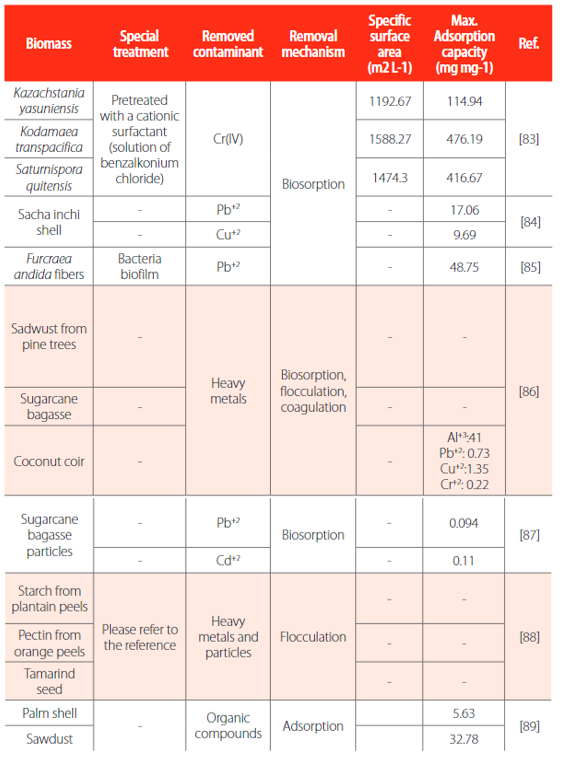

Bioadsorbents from different biological sources have been investigated for removing heavy metals (see Table 3), such as lead, copper, chromium, which commonly end up in rivers, lakes and seas from industrial wastes. Campaña-Pérez et al. [83], reported the adsorption efficiency of three native yeasts for Cr(IV) from simulated wastewater. Kazachstania yasuniensis, Kodamaea transpacifica, and Saturnispora quitensis were isolated from soil samples collected in the Yasuní National Park, ephemeral flower samples from Isabela Island (Galápagos Islands), and fruit of an unidentified species of bramble from Maquipucuna forest reserve in Pichincha, respectively. The use of a cationic surfactant (solution of benzalconium chloride) for yeast conditioning duplicated the biosorption capacity above 80% for Cr(IV ) concentrations up to 100 mg L-1. For instance, the most efficient yeasts Kodamaea transpacifica, and Saturnispora quitensis showed biosorption capacities of about 416 and 476 mg Cr(IV ) per gram of yeast, and specific surface areas, as high as, 1474.30 and 1588.27 m2L-1, respectively. These values have shown the potential of the two isolates as low cost bioremediation agents. Andean Sacha inchi (Plukenetia volubilis) shell biomass (SISB), without any special treatment, has also been reported as a biosorbent for the removal of lead and copper from aqueous solutions. SISB showed adsorption capacities around 17 and 10 mg g-1 for Pb+2 and Cu+2, respectively. Competitive values compared to other low cost bioadsorbents reported in literature [84]. Electrostatic attraction was stated as the mechanism of adsorption between the negatively SIBS surface, and the positively charged contaminants, being optimal at pHs between 3.0 and 6.0. Gallardo-Rodríguez et al. [85] studied bacterial biomass (Pseudomonas strains form aquaculture plants in the Ecuadorian Andes) inoculated on a biofilter packed with Furcraea andina fibers for removing Pb2+ ions. Samples with the bacteria supported on Furcraea andina fibers showed the maximum adsorption capacity of 48.75 mg g-1 at pH of 7. Interestingly, equilibrium batch biosorption assays revealed chemisorption as the Pb+2 removal mechanism.

Summary of adsorption characteristics of different biomasses for wastewater remediation.

Moreover, sugarcane bagasse, sawdust from pine trees, and coconut particles (< 1mm particle size) without chemical modification were also applied for bioadsorption of heavy metals in wastewaters. According to Banchon et al. [86], heavy metals were removed up to 97.8% due to coagulation-flocculation processes were boosted by bioadsorption and ionic strength, reducing the consumption of chemicals (e.g. aluminum and polyacrylamide) up to 70%. In a later study, sugarcane bagasse particles packed in fixed bed columns have been also studied for the biosorption of lead and cadmium [87]. According to the authors, the adsorbents showed greater adsorption capacity for Pb+2 than Cd2+, probably due to its higher electronegativity and smaller hydrated ionic radii. Nonetheless, this capacity was affected when the two contaminants were present in the aqueous media, showing a possible competition between the two ions for active sites at the adsorber. Natural organic polymers extracted from residues, such as starch from plantain peels (Musa paradisiaca L), pectin from orange peels, and tamarind seed extract showed, together with aluminum sulfate, equal or better characteristics as flocculants compared to commercial polymer PAM. Removal values of turbidity and color were around 87% and 92%, respectively, while pH adjustment was not necessary. However, the materials did not present any coagulant activity, and in economic terms, they seem not to be viable [88]. Concerning other contaminants present in produced water from oil and gas industries, Gallo-Cordova et al. [89] studied the adsorption of organic compounds from different residual biomasses (e.g. palm shell, orange, peel, banana peel, passion fruit peel, cocoa bean and sawdust). The adsorption experiments showed that only palm shell and sawdust were able to remove organic compounds from the aqueous media, with adsorption capacities about 5.6 and 32.8 mg g-1 of dry adsorbent.

Biomaterials for biomedical applications

Pupiales et al. [90] have pioneered the evaluation of using biomass waste for the production of porous scaffold via alkaline treatments. Scaffolds were synthetized by alkaline attack (NaOH) and varying reaction parameters, such as biomass concentration, temperature, NaOH concentration, operating time, and mesocarp dimensions (cacao variety CCN-51).

Based on these results, a model was implemented to partially predict the behavior of the output reaction variables (e.g. lignin, cellulose, ash content and yield). Accordingly, NaOH concentration and temperature seemed to be the most important variables for generating porous structures rich in cellulose from cocoa pod shells. This study opened up, a new line of investigation concerning the application of bioporous materials in biomedical applications, e.g. in vitro cytocompatibility, and proliferation and differentiation.

CONCLUSION AND FUTURE DIRECTIONS

This contribution has shortly reviewed not only the most recent studies concerning the conventional chemical, biological and thermochemical conversion processes, but also the latest improvements for making value-added products from Ecuadorian residual biomass.

There is no doubt about Ecuador’s potential to produce and utilize energy from biomass residues. Several studies have shown that conventional transformation methods (e.g. AD, fermentation, and pyrolysis) are better understood at lab-scale, and could be the milestone for scaling up into pilot and big scale plants. Interestingly, recently research articles have also revealed a further valorization of Ecuadorian biomass, aiming at the production of value-added goods, such as hydrogen, and porous materials (adsobers, scaffolds) that open-up new perspectives for a more efficient and environmentally centered bioeconomy. However, there are still several economic and technological challenges to over-come in Ecuador not only related to basic research, but also implementation of renewable-friendly public policies. Therefore, it is crucial the application of the triple helix of innovation, which involves government, university, and industry for the production and dissemination of knowledge in pro of a bio-economy development.

AUTHORS CONTRIBUTION

Sebastián Ponce developed the literature review and prepared the initial draft, José Alvarez Barreto and Daniela Almeida Streitwieser contributed with fruitful discussions, revisions, and preparation of final manuscript.

CONFLICTO DE INTERÉS

Los autores declaran que esta investigación fue conducida en la ausencia de relaciones comerciales o financieras que pudieran constituir un potencial conflicto de interés.

REFERENCES

[1] Shafiee, S., & Topal, E. (2009). When will fossil fuel reserves be diminished? Energy Policy, 37(1), 181-189. doi: https://doi.org/10.1016/j.enpol.2008.08.016

[2] Rahman, M. M., B. Mostafiz, S., Paatero, J. V., & Lahdelma, R. (2014). Extension of energy crops on surplus agricultural lands: A potentially viable option in developing countries while fossil fuel reserves are diminishing. Renewable and Sustainable Energy Reviews, 29, 108-119. doi: https://doi.org/10.1016/j.rser.2013.08.092

[3] Belenky, A. S., Farazmand, A., & Vasin, A. (2019). The Management of Large Scale Energy Projects: Opportunities and Challenges. International Journal of Public Administration, 42(15-16), 1251-1255. doi: https://doi.org/10.1080/01900692.2019.1675929

[4] FVásquez, Z., de Carvalho Neto, D., Pereira, G., Vandenberghe, L., de Oliveira, P., Tiburcio, P., Rogez, H., Góes Neto, A. and Soccol, C., 2019. Biotechnological approaches for cocoa waste management: A review. Waste Management, [online] 90, pp.72-83. Available at: https://doi.org/10.1016/j.wasman.2019.04.030 [Accessed 26 August 2021].

[5] Hache, E. (2018). Do renewable energies improve energy security in the long run? International Economics, 156, 127135. doi: https://doi.org/10.1016/j.inteco.2018.01.005

[6] Barreto, R. A. (2018). Fossil fuels, alternative energy and economic growth. Economic Modelling, 75, 196-220. doi: https://doi.org/10.1016/j.econmod.2018.06.019

[7] Vásquez, Z., de Carvalho Neto, D., Pereira, G., Vandenberghe, L., de Oliveira, P., Tiburcio, P., Rogez, H., Góes Neto, A. and Soccol, C., 2019. Biotechnological approaches for cocoa waste management: A review. Waste Management, [online] 90, pp.72-83. Available at: https://doi.org/10.1016/j.wasman.2019.04.030 [Accessed 26 August 2021].

[8] Popp, J., Lakner, Z., Harangi-Rákos, M., & Fári, M. (2014). The effect of bioenergy expansion: Food, energy, and environment. Renewable and Sustainable Energy Reviews, 32, 559-578. doi: https://doi.org/10.1016/j.rser.2014.01.056

[9] Gamborg, C., Millar, K., Shortall,O., & Sandøe, P. (2012). Bioenergy and Land Use: Framing the Ethical Debate. Journal of Agricultural and Environmental Ethics, 25(6), 909-925. doi: https://doi.org/10.1007/s10806-011-9351-1

[10] Edelmann, W., Schleiss, K., & Joss, A. (2000). Ecological, energetic and economic comparison of anaerobic digestion with different competing technologies to treat biogenic wastes. Water Science and Technology, 41(3), 263-273. doi: https://doi.org/10.2166/wst.2000.0080

[11] Nallathambi Gunaseelan, V. (1997). Anaerobic digestion of biomass for methane production: A review. Biomass and Bioenergy, 13(1), 83-114. doi: https://doi.org/10.1016/S0961-9534(97)00020-2

[12] Margallo, M., Ziegler-Rodriguez, K., Vázquez-Rowe, I., Aldaco, R., Irabien, Á., & Kahhat, R. (2019). Enhancing waste management strategies in Latin America under a holistic environmental assessment perspective: A review for policy support. Science of The Total Environment, 689, 1255-1275. doi: https://doi.org/10.1016/j.scitotenv.2019.06.393

[13] UN-HABITAT. (2010). 2010 WTE industry in Latin America. Retrieved from https://mirror.unhabitat.org/downloads/docs/10740_1_594319.pdf

[14] Hidalgo-Crespo, J., Amaya, J., Jervis, F., Moreira, C., Crespo-Vaca, T., Zabala-Ortiz, G., & Coello-Pisco, Revista Ibérica de Sistemas e Tecnologías de Informando (2019). Waste-To-Energy Incineration: Evaluation of energy potential for urban domestic waste in Guayaquil. (E23), 392-403.

[15] Posso, F., Siguencia, J., & Narváez, R. (2020). Residual biomass-based hydrogen production: Potential and possible uses in Ecuador. International Journal of Hydrogen Energy, 45(26), 13717-13725. doi: https://doi.org/10.1016/j.ijhydene.2019.09.235

[16] Sa, E. C. (2014). Atlas bioenergético del Ecuador. Recuperado de: http://www.energia.gob.ec/biblioteca/(Agosto, 2016).

[17] Garcia M, J. C., Machimura, T., & Matsui, T. (2012). Optimizing Plant Allocation for Bioethanol Production from Agro-residues Considering CO2 Emission and Energy Demand-Supply Balance: A Case Study in Ecuador. Waste and Biomass Valorization, 3(4), 435-442. doi: https://doi.org/10.1007/s12649-012-9138-2

[18] Garcia, J., Machimura, T., & Matsui, T. (2013). A Nation-wide Planning of Agro-residue Utility for Bioethanol Production and Power Generation in Ecuador. Energy Procedia, 34, 57-63. doi: https://doi.org/10.1016/j.egypro.2013.06.733

[19] Vega-Quezada, C., Blanco, M., & Romero, H. (2017). Synergies between agriculture and bioenergy in Latin American countries: A circular economy strategy for bioenergy production in Ecuador. New Biotechnology, 39, 81-89. doi: https://doi.org/10.1016/j.nbt.2016.06.730

[20] Garcia, J., Machimura, T., Matsui, T., & Miyauchi, T. (2014). Estimating the potential and planning of bioethanol production from agro-residues based on a model-predicted NPP under climate change in Ecuador. Journal of Agricultural Meteorology, 70(4), 171-185. doi: https://doi.org/10.2480/agrmet.D-13-00027

[21] Barragán-Escandón, A., Olmedo Ruiz, J. M., Curillo Tigre, J. D., & Zalamea-León, E. F. (2020). Assessment of Power Generation Using Biogas from Landfills in an Equatorial Tropical Context. Sustainability, 12(7). doi: https://doi.org/10.3390/su12072669

[22] Heredia Salgado, M., Tarelho, L., Matos, M., Rivadeneira, D., & Narváez C, R. (2019). Palm oil kernel shell as solid fuel for the commercial and industrial sector in Ecuador: tax incentive impact and performance of a prototype burner. Journal Of Cleaner Production, 213, 104-113. doi: https://doi.org/10.1016/j.jclepro.2018.12.133

[23] Peláez-Samaniego, M., & Espinoza Abad, J. (Eds.) (2015). Energías renovables en el Ecuador. Situación actual, tendencias y perspectivas (1st ed., pp. 29-115). Cuenca, Ecuador: Universidad de Cuenca.

[24] Loor, M. C., Andrade, F., Lizarzaburu, L., & Masache, M. (2017). Valoración económica de los cobeneficios del aprovechamiento energético de los residuos agrícolas en el Ecuador. Retrieved from https://repositorio.cepal.org/handle/11362/41830

[25] Cornejo, C., & Wilkie, A. C. (2010). Greenhouse gas emissions and biogas potential from livestock in Ecuador. Energy for Sustainable Development, 14(4), 256-266. doi: https://doi.org/10.1016/j.esd.2010.09.008

[26] Jara-Samaniego, J., Pérez-Murcia, M. D., Bustamante, M. A., Paredes, C., Pérez-Espinosa, A., Gavilanes-Terán, I., . . . Moral, R. (2017). Development of organic fertilizers from food market waste and urban gardening by composting in Ecuador. PLOS ONE, 12(7), e0181621. doi: https://doi.org/10.1371/journal.pone.0181621

[27] Serrano, J., Mejía, W., Ortiz, J., Sánchez, A., & Zalamea, S. (2017). Determinación del Potencial de Generación Eléctrica a Partir de Biomasa en el Ecuador. Revista de la Facultad de Ciencias Químicas, 17, 41-61. https://publicaciones.ucuenca.edu.ec/ojs/index.php/quimica/article/view/1592

[28] Ponce-Jara, M. A., Castro, M., Pelaez-Samaniego, M. R., Espinoza-Abad, J. L., & Ruiz, E. (2018). Electricity sector in Ecuador: An overview of the 2007-2017 decade. Energy Policy, 113, 513-522. doi: https://doi.Org/10.1016/j.enpol.2017.11.036

[29] Agencia de Regulación y Control de Electricidad del Ecuador (ARCONEL). (2018). Estadística Anual y Multianual del Sector Eléctrico Ecuatoriano (pp. 9-30). Quito: ARCONEL. Retrieved from https://www.regulacionelectrica.gob.ec/wp-content/uploads/downloads/2019/08/Estad%C3%ADsticaAnualMultianual2018.pdf

[30] Rivera-González, L., Bolonio, D., Mazadiego, L. F., & Valencia-Chapi, R. (2019). Long-Term Electricity Supply and Demand Forecast (2018-2040): A LEAP Model Application towards a Sustainable Power Generation System in Ecuador. Sustainability, 11(19). doi: https://doi.org/10.3390/su11195316

[31] Vaca-Jiménez, S., Gerbens-Leenes, P. W., & Nonhebel, S. (2019). The water footprint of electricity in Ecuador: Technology and fuel variation indicate pathways towards water-efficient electricity mixes. Water Resources and Industry, 22, 100112. doi: https://doi.org/10.1016/j.wri.2019.100112

[32] MERNNR. (2019). Ministerio de Energía y Recursos Naturales no Renovables: K007 Producción de Aceite de Piñón para plan piloto de generación eléctrica en Galápagos - Fase II. Retrieved from https://www.recursosyenergia.gob.ec/wp-content/uploads/2019/11/gprproduccion-aceite-pinon.pdf

[33] Narváez C, R. A., Ramírez, V., Chulde, D., Espinoza, S., & López-Villada, J. (2015). Microwave Pyrolysis Process Potential of Waste Jatropha Curcas Seed Cake. In A. Sayigh (Ed.), Renewable Energy in the Service of Mankind Vol I: Selected Topics from the World Renewable Energy Congress WREC 2014 (pp. 91-100). Cham: Springer International Publishing.

[34] Garfí, M., Martí-Herrero, J., Garwood, A., & Ferrer, I. (2016). Household anaerobic digesters for biogas production in Latin America: A review. Renewable and Sustainable Energy Reviews, 60, 599-614. doi: https://doi.org/10.1016/j.rser.2016.01.071

[35] Mao, C., Feng, Y., Wang, X., & Ren, G. (2015). Review on research achievements of biogas from anaerobic digestion. Renewable and Sustainable Energy Reviews, 45, 540-555. doi: https://doi.org/10.1016/j.rser.2015.02.032

[36] Chen, Y., Cheng, J. J., & Creamer, K. S. (2008). Inhibition of anaerobic digestion process: A review. Bioresource Technology, 99(10), 4044-4064. doi: https://doi.org/10.1016/j.biortech.2007.01.057

[37] Davis, M. J. M., Polit, D. J., & Lamour, M. (2016). Social Urban Metabolism Strategies (SUMS) for Cities. Procedia Environmental Sciences, 34, 309-327. doi: https://doi.org/10.1016/j.proenv.2016.04.028

[38] Aguilar, M., Wang, Y., Roskilly, T., Pathare, P., & Lamidi, R. (2017). Biogas from anaerobic co-digestion of food waste and primary sludge for cogeneration of power and heat. Energy Procedia, 142, 70-76. doi: 10.1016/j.egypro.2017.12.012

[39] Leyva, L., Santos, Y., Granda, I., Orges, C., Palacios, S., & Chapi, R. Design of a Lab-scale Anaerobic Biodigester for Renewable Energy from Municipal Solid Waste. Proceedings of the International Conference on Industrial Engineering and Operations Management. Washington DC, USA, September 27-29, 2018. págs. 705-714

[40] Castelo, P., Peñafiel, R., & Ochoa-Herrera, V. (2014). Digestión anaeróbica de desechos de frutas y hortalizas en reactores semicontinuos de un mercado municipal en Tumbaco, Ecuador. ACI Avances En Ciencias E Ingenierías, 6(2), 31-39. doi: https://doi.org/10.18272/aci.v6i2.185

[41] Romero, H. I., Vega, C. A., Zuma, J. D., Pesantez, F. F., Camacho, A. G., & Redrovan, F. F. (2020). Comparison of the methane potential obtained by anaerobic codigestion of urban solid waste and lignocellulosic biomass. Energy Reports, 6, 776-780. doi: https://doi.org/10.1016/j.egyr.2019.10.013

[42] Gaibor-Chávez, J., Niño-Ruiz, Z., Velázquez-Martí, B., & Lucio-Quintana, A. (2019). Viability of Biogas Production and Determination of Bacterial Kinetics in Anaerobic Co-digestion of Cabbage Waste and Livestock Manure. Waste and Biomass Valorization, 10(8), 2129-2137. doi: https://doi.org/10.1007/s12649-018-0228-7

[43] Barzallo-Bravo, L. A., Carrera-Villacrés, D., Vargas-Verdesoto, R. E., Ponce-Loaiza, L. K., Correoso, M., & Gavilanes- Quishpi, Á. P. (2019). Bio-digestion and post-treatment of effluents by bio-fermentation, an opportunity for energy uses and generation of organic fertilizers from bovine manure. International Journal of Recycling of Organic Waste in Agriculture, 8(4), 431-438. doi: https://doi.org/10.1007/s40093-019-0275-5

[44] Muñoz Espinoza, M., Barros-Rodríguez, M., Valencia Nuñez, R., Mera Andrade, R., Artieda-Rojas, J., Najarro, R. N., Romero Fernández, A. (2019). Biogas Production and in Vitro CH4 from Excrement of Cattle, Sheep, Pigs and Hen. Tropical and Subtropical Agroecosystems, 22(2019), 833-836. https://www.revista.ccba.uady.mx/ojs/index.php/TSA/article/view/3084tsaes.v22i3.3084

[45] Mantuano, J., Macías, M., Toapanta, E., Palma, K., & Giraldo, M. (2020). Obtaining biogas product from biological residues vaccines in Chone city. International Journal Of Physical Sciences And Engineering, 4(1), 21-28. doi: https://doi.org/10.29332/ijpse.v4n1.416

[46] Diéguez-Santana, K., González, E. C., Pérez-Martínez, A., & Herrera-Robledo, M. (2018). The Pig Manure Anaerobic Digestion. A tubular biodigester characterization in the Ecuadorian Amazon. Paper presented at the Proceedings of MOL2NET 2018, International Conference on Multidisciplinary Sciences, 4th edition.

[47] Almeida Streitwieser, D., & Cadena Cabezas, I. (2018). - Preliminary Study of Biomethane Production of Organic Waste based on their Content of Sugar, Starch, Lipid, Protein and Fibre. Chemical Engineering Transactions, 65, 661-666. doi: https://doi.org/10.3303/CET1865111

[48] Acosta, N., De Vrieze, J., Sandoval, V., Sinche, D., Wierinck, I., & Rabaey, K. (2018). Cocoa residues as viable biomass for renewable energy production through anaerobic digestion. Bioresource Technology, 265, 568-572. doi: https://doi.org/10.1016/j.biortech.2018.05.100

[49] Gavilanes, F. Z., Guedes, C. L. B., Silva, H. R., Nomura, R. G., & Andrade, D. S. (2019). Physic Nut Seed Cake Methanation and Chemical Characterization of Anaerobic Bio-digested Substrate. Waste and Biomass Valorization, 10(5), 12671276. doi: https://doi.org/10.1007/s12649-017-0148-y

[50] Pazmiño-Hernandez, M., Moreira, C. M., & Pullammanappallil, P. (2019). Feasibility assessment of waste banana peduncle as feedstock for biofuel production. Biofuels, 10(4), 473-484. doi: https://doi.org/10.1080/17597269.2017.1323321

[51] Almeida Streitwieser, D. (2017). Comparison of the anaerobic digestion at the mesophilic and thermophilic temperature regime of organic wastes from the agribusiness. Bioresource Technology, 241, 985-992. doi: https://doi.org/10.1016/j.biortech.2017.06.006

[52] Mohd Azhar, S., Abdulla, R., Jambo, S., Marbawi, H., Gansau, J., Mohd Faik, A., & Rodrigues, K. (2017). Yeasts in sustainable bioethanol production: A review. Biochemistry And Biophysics Reports, 10, 52-61. doi: https://doi.10.1016/j.bbrep.2017.03.003

[53] Bušić, A., Marđetko, N., Kundas, S., Morzak, G., Belskaya, H., Ivančić Šantek, M., . . . Šantek, B. (2018). Bioethanol Production from Renewable Raw Materials and Its Separation and Purification: A Review. Food technology and biotechnology, 56(3), 289-311. doi:https://doi.org/10.17113/ftb.56.03.18.5546

[54] Graefe, S., Dufour, D., Giraldo, A., Muñoz, L. A., Mora, P., Solís, H., . . . Gonzalez, A. (2011). Energy and carbon footprints of ethanol production using banana and cooking banana discard: A case study from Costa Rica and Ecuador. Biomass and Bioenergy, 35(7), 2640-2649. doi: https://doi.org/10.1016/j.biombioe.2011.02.051

[55] Guerrero, A. B., & Muñoz, E. (2018). Life cycle assessment of second generation ethanol derived from banana agricultural waste: Environmental impacts and energy balance. Journal of Cleaner Production, 174, 710-717. doi: https://doi.org/10.1016/j.jclepro.2017.10.298

[56] Velazquez-Marti, B., Pérez-Pacheco, S., Gaibor-Chávez, J., & Wilcaso, P. (2016). Modeling of Production and Quality of Bioethanol Obtained from Sugarcane Fermentation Using Direct Dissolved Sugars Measurements. Energies, 9(5), 319. doi: https://doi.org/10.3390/en9050319

[57] BMacías, C., & Palacios, A. (2017). Estudio cinético de la producción de bioetanol a partir de residuos agroindustriales de cáscara de banano maduro (Undergraduate). Universidad Técnica de Machala.

[58] Costa, S., Rugiero, I., Larenas Uria, C., Pedrini, P., & Tamburini, E. (2018). Lignin Degradation Efficiency of Chemical Pre-Treatments on Banana Rachis Destined to Bioethanol Production. Biomolecules, 8(4), 141. doi: https://doi.org/10.3390/biom8040141

[59] Portero-Barahona, P., Carvajal-Barriga, E., Martín-Gil, J., & Martín-Ramos, P. (2019). Sugarcane Bagasse Hydrolysis Enhancement by Microwave-Assisted Sulfolane Pretreatment. Energies, 12(9), 1703. doi: https://doi.org/10.3390/en12091703

[60] Pérez-Arévalo, J. J., & Velázquez-Martí, B. (2018). Evaluation of pruning residues of Ficus benjamina as a primary biofuel material. Biomass and Bioenergy, 108, 217-223. doi: https://doi.org/10.1016/j.biombioe.2017.11.017

[61] Velázquez-Martí, B., Gaibor-Cházvez, J., Niño-Ruiz, Z., & Narbona-Sahuquillo, S. (2018). Complete characterization of pruning waste from the lechero tree (Euphorbia laurifolia L.) as raw material for biofuel. Renewable Energy, 129, 629-637. doi: https://doi.org/10.1016/j.renene.2018.06.050

[62] Larrea, F. A., Salazar, S., Andino, C., Ona, D., Mora, J., Streitwieser, D. A., & Alvarez-barreto, J. F. (2020). Comparison of Bioethanol Production of Starches from Different Andean Tubers. CHEMICAL ENGINEERING TRANSACTIONS, 80(April), 259-264. https://doi.org/10.3303/CET2080044

[63] Carvajal Barriga, E. J., Guamn-Burneo, C., Portero, P., Salas, E., Tufio, C., & Bastidas, B. (2013). Second Generation Ethanol from Residual Biomass: Research and Perspectives in Ecuador. In C. Guamán-Burneo (Ed.), Biomass Now - Sustainable Growth and Use (p. Ch. 10). Rijeka: InTech. https://doi.org/10.5772/51951

[64] Kumar, A., Jones, D., & Hanna, M. (2009). Thermochemical Biomass Gasification: A Review of the Current Status of the Technology. Energies, 2(3), 556-581. doi: https://doi.org/10.3390/en20300556

[65] Nussbaumer, T. (2003). Combustion and Co-combustion of Biomass: Fundamentals, Technologies, and Primary Measures for Emission Reduction. Energy & Fuels, 17(6), 1510-1521. doi: https://doi.org/10.1021/ef030031q

[66] Vargas, D. C., Salazar, S., Mora, J. R., Van Geem, K. M., & Almeida Streitwieser, D. (2020). Experimental and theoretical study of the thermal decomposition of ethyl acetate during fast pyrolysis. Chemical Engineering Research and Design, 157, 153-161. doi:https://doi.org/10.1016/j.cherd.2020.03.001

[67] Choi, M. K., Park, H. C., & Choi, H. S. (2018). Comprehensive evaluation of various pyrolysis reaction mechanisms for pyrolysis process simulation. Chemical Engineering and Processing - Process Intensification, 130, 19-35. doi: https://doi.org/10.1016/j.cep.2018.05.011

[68] Bridgwater, A. V. (2012). Upgrading biomass fast pyrolysis liquids. Environmental Progress & Sustainable Energy, 31(2), 261-268. doi: https://doi.org/10.1002/ep.11635

[69] Pérez-Arévalo, J. J., Callejón-Ferre, A. J., Velázquez-Martí, B., & Suárez-Medina, M. D. (2015). Prediction models based on higher heating value from the elemental analysis of neem, mango, avocado, banana, and carob trees in Guayas (Ecuador). Journal of Renewable and Sustainable Energy, 7(5), 053122. doi: https://doi.org/10.1063/1.4934593

[70] Pérez Arévalo, J. J., & Velázquez Martí, B. (2020). Characterization of teak pruning waste as an energy resource. Agroforestry Systems, 94(1), 241-250. doi: https://doi.org/10.1007/s10457-019-00387-3

[71] Ghysels, S., Estrada Léon, A. E., Pala, M., Schoder, K. A., Van Acker, J., & Ronsse, F. (2019). Fast pyrolysis of mannan-rich ivory nut (Phytelephas aequatorialis) to valuable biorefinery products. Chemical Engineering Journal, 373, 446-457. doi: https://doi.org/10.1016/j.cej.2019.05.042

[72] Rivadeneira, D., Ramírez, V., Narváez, R., Heredia, M., Antonio da Cruz, L., & Amador-de Matos, A. (2017). First analysis of emissions during the combustion of pellets of Jatropha curcas at 2635 masl. Investigación y Saberes, 3(3), 65-79. https://www.researchgate.net/publication/322405943_PRIMER_ANALISIS_DE_EMISIONES_DURANTE_LA_COMBUSTION_DE_PELLETS_DE_JATROPHA_CURCAS_A_2635_MSNM_FIRST_ANALYSIS_OF_EMISSIONS_DURING_THE_COMBUSTION_OF_PELLETS_OF_JATROPHA_CURCAS_AT_2635_MASL

[73] Ramírez, V., Martí-Herrero, J., Romero, M., & Rivadeneira, D. (2019). Energy use of Jatropha oil extraction wastes: Pellets from biochar and Jatropha shell blends. Journal of Cleaner Production, 215, 1095-1102. doi:https://doi.org/10.1016/j.jclepro.2019.01.132

[74] Heredia Salgado, M. A., Tarelho, L. A. C., Rivadeneira, D., Ramírez, V., & Sinche, D. (2020). Energetic valorization of the residual biomass produced during Jatropha curcas oil extraction. Renewable Energy, 146, 1640-1648. doi:https://doi.org/10.1016/j.renene.2019.07.154

[75] Heredia, M. (2017). Cuesco de palma africana , un nuevo combustible para uso comercial en Ecuador : análisis económico y evidencia experimental. Aveiro. Retrieved from https://www.researchgate.net/publication/316844319

[76] Heredia Salgado, M. A., Coba S, J. A., & Tarelho, L. A. C. (2020). Simultaneous production of biochar and thermal energy using palm oil residual biomass as feedstock in an auto-thermal prototype reactor. Journal of Cleaner Production, 266, 121804. doi:https://doi.org/10.1016/j.jclepro.2020.121804

[77] Salgado, M. A. H., Tarelho, L. A. C., & Matos, A. (2020). Analysis of Combined Biochar and Torrefied Biomass Fuel Production as Alternative for Residual Biomass Valorization Generated in Small-Scale Palm Oil Mills. Waste and Biomass Valorization, 11(1), 343-356. doi: https://doi.org/10.1007/s12649-018-0467-7

[78] Teichmann, D., Arlt, W., & Wasserscheid, P. (2012). Liquid Organic Hydrogen Carriers as an efficient vector for the transport and storage of renewable energy. International Journal of Hydrogen Energy, 37(23), 18118-18132. doi:https://doi.org/10.1016/j.ijhydene.2012.08.066

[79] Runge, P, Sölch, C., Albert, J., Wasserscheid, P, Zöttl, G., & Grimm, V. (2019). Economic comparison of different electric fuels for energy scenarios in 2035. Applied Energy, 233-234, 1078-1093. doi: https://doi.org/10.1016/j.apenergy.2018.10.023

[80] Posso, F., Narváez C, R. A., Siguencia, J., & Sánchez, J. (2019). Use of Municipal Solid Waste (MSW)-Derived Hydrogen in Ecuador: Potential Applications for Urban Transportation. Waste and Biomass Valorization, 10(6), 1529-1537. doi: https://doi.org/10.1007/s12649-017-0161-1

[81] Narváez, R., Vargas, G., & Espinoza, F. (2013). Potential of Waste-to- Energy Implementation in Ecuador. International Journal of Energy Engineering, 3(6), 279-286. doi: https://doi.org/10.5923/j.ijee.20130306.01

[82] Davis, M. E. (2002). Ordered porous materials for emerging applications. Nature, 417(6891), 813-821. doi: https://doi.org/10.1038/nature00785

[83] Campaña-Pérez, J. F., Portero Barahona, P., Martín-Ramos, P., & Carvajal Barriga, E. J. (2019). Ecuadorian yeast species as microbial particles for Cr(VI) biosorption. Environmental Science and Pollution Research, 26(27), 28162-28172. doi: https://doi.org/10.1007/s11356-019-06035-8

[84] Kumar, B., Smita, K., Sánchez, E., Stael, C., & Cumbal, L. (2016). Andean Sacha inchi (Plukenetia volubilis L.) shell biomass as new biosorbents for Pb2+ and Cu2+ ions. Ecological Engineering, 93, 152-158. doi: https://doi.org/10.1016/j.ecoleng.2016.05.034

[85] Gallardo-Rodríguez, J. J., Rios-Rivera, A. C., & Von Bennevitz, M. R. (2019). Living biomass supported on a naturalfiber biofilter for lead removal. Journal of Environmental Management, 231, 825-832. doi:https://doi.org/10.1016/j.jenvman.2018.11.004

[86] Banchon, C., Castillo, A., & Posligua, P. (2017). Chemical interactions to cleanup highly polluted automobile service station wastewater by bioadsorption-coagulation-flocculation. Journal of Ecological Engineering, 18(1), 1-10. doi: https://doi.org/10.12911/22998993/66252

[87] Vera, L. M., Bermejo, D., Uguña, M. F., Garcia, N., Flores, M., & González, E. (2019). Fixed bed column modeling of lead(II) and cadmium(II) ions biosorption on sugarcane bagasse. Environmental Engineering Research, 24(1), 31-37. doi: https://doi.org/10.4491/eer.2018.042

[88] Aldás Sandoval, M. B., Buenaño Bautista, B. B., & Vera Calle, E. R. (2019). Study of coagulating/flocculating characteristics of organic polymers extracted from biowaste for water treatment. Ingeniería e Investigación, 39(1), 24-35. https://doi.org/10.15446/ing.investig.v39n1.69703

[89] Gallo-Cordova, A., Silva-Gordillo, M. d. M., Muñoz, G. A., Arboleda-Faini, X., & Almeida Streitwieser, D. (2017). Comparison of the adsorption capacity of organic compounds present in produced water with commercially obtained walnut shell and residual biomass. Journal of Environmental Chemical Engineering, 5(4), 4041-4050. doi: https://doi.org/10.1016/j.jece.2017.07.052

[90] Pupiales, B., Galeas, S., Guerrero, V., Proano, J., Leon, M., & Alvarez-Barreto, J. (2020). Generation of porous scaffolds from cacao mesocarp for biomedical applications using surface response methodology. Chemical Engineering Transactions, 79(October 2019), 151-156. https://doi.org/10.3303/CET2079026